By Bob Ward, Product Manager, Actuators, Rollon USA

Actuators are useful in a range of industrial applications. Each application, though, has unique requirements of these devices. These tips will ensure you select the right actuator for your heavy duty packaging or top sealer packaging machine.

The task of selecting, sizing and applying linear actuators involves many variables, from stroke length and duty cycle to precision and accuracy requirements. Ultimately, matching the right actuator to the intended application requires a close look at all of the specifications involved and then, of course, working within the project’s performance, time and budget constraints.

Certain manufacturing operations are more rigorous than others, with end-of-line packaging applications among the most demanding for linear actuation. Activities such as palletizing, case packing with hdpe sheets, cartoning with kraft tubes, and lane diverting require strong and reliable motion components. Here is a look at some of the most important aspects to consider when selecting actuators for these heavy-duty packaging operations.

1. Precision and accuracy.

What level of precision, accuracy and repeatability does the application demand? In the majority of end-of-line packaging applications involving actuators, positioning repeatability to 50 μm is acceptable. Consider a SCARA robot with a vacuum end effector or other gripper sitting atop a linear actuator. The actuator is used to linearly move the robot into various positions so that the end effector can pick up cases and move them onto pallets.

Motion must be repeatable, reliable and fairly precise for the robot to do its job, though pinpoint accuracy is rarely needed in this scenario. However, for tasks requiring more precise positioning, ask your actuator supplier about the option of adding a linear encoder.

2. Load capacity.

Think about the loads, moments and forces that the actuator must handle. For heavy-duty packaging applications, this will likely involve some fairly demanding dynamic load capacities. How much load can the actuator handle during high speeds and acceleration? Take a close look at the actuator’s specifications for thrust capacity, dynamic load capacity, and bending moments.

Load capacity is directly related to the internal construction of an actuator. While many linear actuators look similar from the outside, some are built to handle high loads at high speeds, while others may only support light loads at high speeds.

Note: Pay special attention to units when comparing actuators. Some manufacturers use SI/metric figures, while others use U.S. customary or imperial units. Be sure you are making an apples-to-apples comparison when looking at specifications data.

3. Travel length and space.

Determine the required stroke length as well as the volumetric envelope the system must fit into. For example, will the actuator be used to move a robot into position? If so, how far will the robot need to travel on its linear path? Or will several actuators be used to create a Cartesian gantry system to move cases around?

In certain end-of-line packaging scenarios, it makes sense to build a three-axis gantry system out of heavy-duty rigid actuators to handle heavy loads rather than using a SCARA robot with a more limited payload capacity. In many cases, a gantry system may require the same or less volumetric space than a comparable SCARA robot system.

4. Duty cycle.

Consider the application’s motion profile, duty cycle, cycle time and dwell time in addition to lifetime requirements. Many packaging applications such as palletizing and cartoning require nearly constant motion as actuators move back and forth between different positions.

Be sure to ask your actuator supplier about maintenance and lubrication schedules as well. Some actuators only need relubrication after a service life of 20,000 km, while others demand more frequent attention.

5. Operating environment.

What are the working conditions the actuator and larger system will be subjected to? Will special seals or bellows be required to protect the actuator’s moving parts from dust, moisture or other contaminants? Ask your supplier if these are available.

6. Spatial orientation.

How will the actuator be oriented in the available space? How will loads and forces be oriented? Consider mounting options as well.

Many packaging operations call for horizontal mounting, though vertical mounting is often required in multiaxis systems and for operations such as shrink-wrapping. The more information provided to your actuator supplier in the early stages of system design, the more successful your application will be.

In addition, consider the linkages between actuators in multi-axis setups. Some suppliers provide fittings such as brackets and cross plates designed to rigidly connect actuators to each other, while others leave these connection tasks to the end user. Improperly connected systems can lead to problems with misalignment, vibration, reduced accuracy and, ultimately failure.

7. Speed and acceleration.

To select the proper actuator for the packaging task, one must first know the travel speed in addition to the required acceleration and deceleration rates. Does the actuator need to quickly match the speed of a moving conveyor belt to be able to grab cartons at a certain point and then move those cartons to a pallet?

Perhaps a robot needs to be moved into position for a few seconds while it completes a pick-and-place motion and then must be retracted to its original position. These are the details your actuator supplier will need to know. Some heavy-duty actuators can support high loads at speeds to 5 m/s while others are more limited in their speeds and load capacities.

8. Actuator construction.

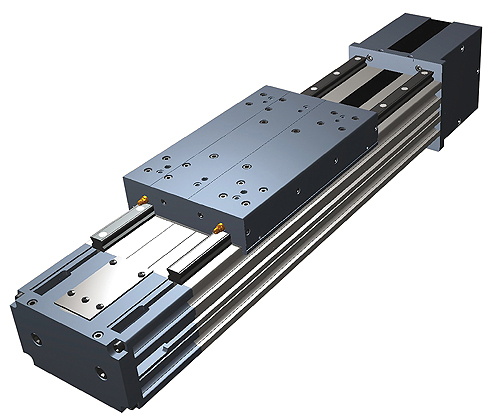

As mentioned earlier, many actuators share a similar appearance at first glance. Most are made of anodized aluminum extrusions for high strength and low weight, but this is where the similarities often end. When specifying an actuator for the heavy usage and demanding loads involved in end-of-line packaging operations, it pays to look closer.

One area of interest is the guide system. Look for pre-loaded linear guides, which help improve the accuracy, repeatability and stiffness of the entire moving system. Rubber coated or plastic guide wheels may work fine at the outset, but are not nearly as long lasting or rigid as preloaded guides. Consider the bearings as well. Pre-loaded linear bearings made of machine tool grade steel go a long way toward increasing system stiffness and accuracy.

In the case of belt-driven actuators, another area to look at involves shaft and pulley construction. Look for steel pulleys for strength and longevity. Also consider how the shaft and pulley assembly is made: Assemblies that are machined from one piece of steel mean that the pulley cannot slip on the shaft, in contrast to multiple component arrangements where the pulley is press-fit to the shaft.

In addition, look for pulleys that use sturdy bolt-on flanges to guide the belt as opposed to lightweight flanges that are pressed on or formed in with the pulley. Finally, look for preloaded radial ball bearings on the pulley drive rather than plastic or bronze bushings. All of these details add up to a heavy-duty actuator that can handle the punishing loads of end-of-line packaging applications.

9. Gearbox and motor matching.

When it comes to specifying high speed belt-driven actuators for demanding packaging operations, more than 95% will require a gearbox or speed reducer for inertia matching and as a torque multiplier. Some actuator suppliers include integrated planetary gearboxes as part of a complete actuator assembly to make specification simpler.

Another area to inquire about involves motor sizing data. Ask your actuator supplier if they can provide detailed application-engineering data to your motor manufacturer so that the entire system is matched correctly to the intended application. Some suppliers offer this pre-engineering documentation as part of a comprehensive quote.

Save space and money with belt-driven actuators

Have you looked into robots and large pieces of capital equipment for palletizing in-process or finished goods for shipping? These machines can take up a lot of space and potentially cause bottlenecks that form when processes are stationed too close to each other.

But the use of belt-driven actuators can solve many of the space issues. These devices are a simple, readily available system capable of being outfitted with any control or motor package so it can be conveniently integrated into an existing plant management software infrastructure. They can be easily designed in many configurations.

The benefits of belt-driving actuators can be shown by comparing two common examples based on a standard conveyor to palletizer setup used in many industries.

6-axis robot. A 6-axis robot can build pallets of cases that consist of in-process or finished products. Cases stacked up to 60 ft require a standard pallet that measures 48 in. by 40 in. A robotic arm with a minimum reach of 96 in. is required to account for the increased distance the arm has to travel in an arc. An arm this size can cost upwards of $50,000. Additionally, a 90-degree rotation requires roughly 200 ft2 of floor space to pick up a case.

Aside from the space and cost estimates, there are several safety requirements needed for installing a robot on a manufacturing floor:

• Safety cage

• Lock out tag system

• Light curtains

• Emergency stop

On the other hand, a multi-axis belt-driven gantry for the same application can occupy the same space as the conveyor and pallet. Taking into account the mounting structure and safety stroke of the actuators, this would account for up to 10 ft2 of floor space and between $6,000 and $7,000 per axis, totaling in at $28,000 for a 3-axis, 4-actuator gantry.

Vertical palletizer. A vertical palletizer can be used if the conveyor line is overhead. If the product isn’t transferred overhead, the machine needs a special inclined conveyor that requires larger motion components to move the product against the force of gravity. In most setups, the machine builds each layer of the pallet and lowers it while simultaneously building the next layer. The layers require rotating packages to form the correct pattern, a process that adds cost to the conveyor because it must be done upstream from the system. They must also be large and strong so they can hold the weight of a growing pallet. This snowball effect can cause some of these machines to cost up to $100,000 and they can take up 300 square feet of space.

A gantry similar to the first example, with an additional vertical lift unit for an elevated conveyor setup, would cost roughly $35,000 and take up no more than 10 percent of the required space.

Rollon USA

www.rollon.com

Leave a Reply

You must be logged in to post a comment.