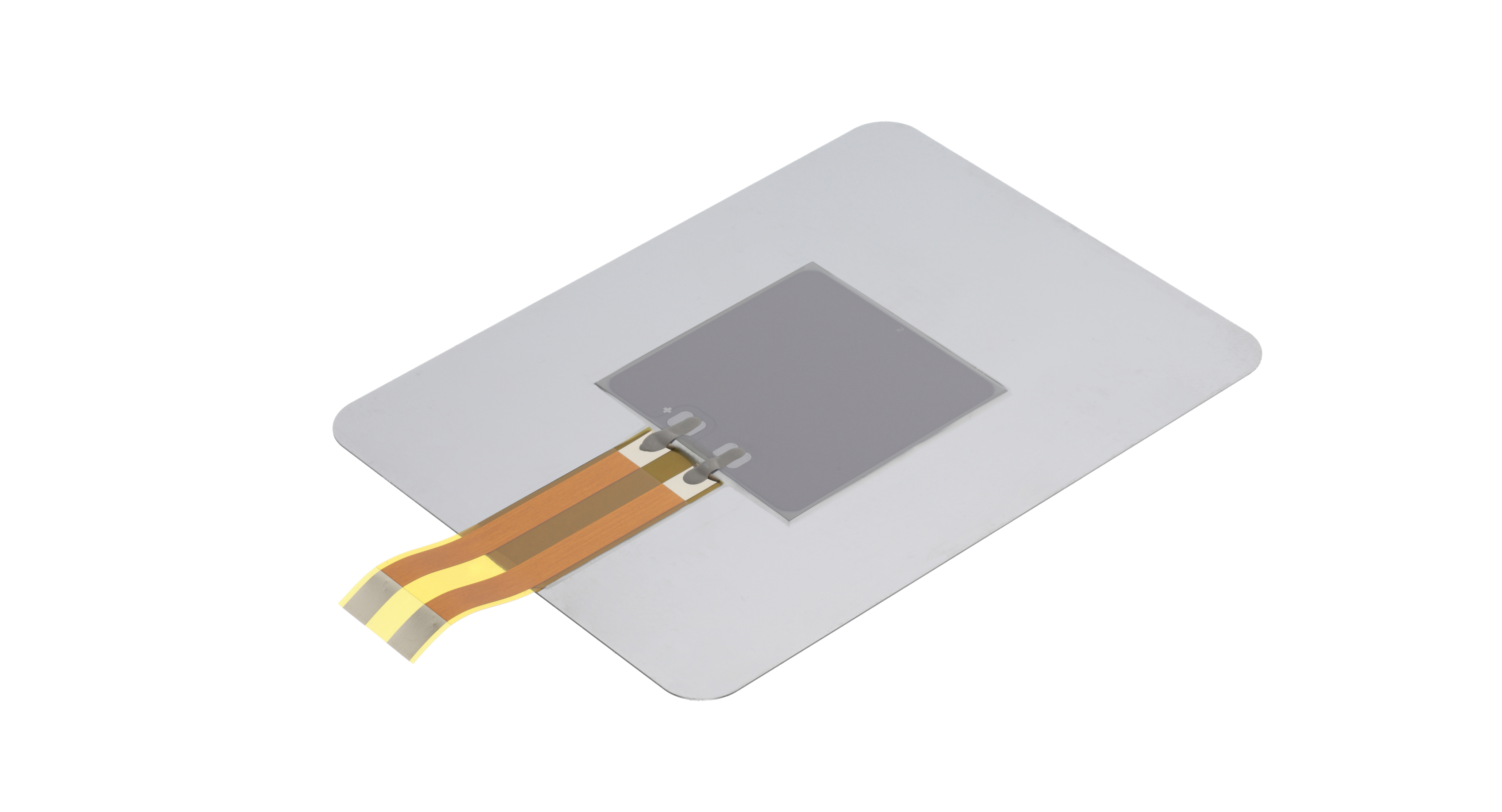

TDK now sells a new haptic component — a new ultra-thin PiezoHapt actuator featuring a short response time of just 4 msec. PiezoHapt has a unimorph design consisting of a multilayer piezo element bonded to one side of a vibration plate. With a thickness of a mere 0.35 mm the new haptic actuator is much thinner than conventional eccentric rotary motors and linear resonant actuators, and one of the world’s thinnest haptic devices. Moreover, thanks to its fast rise time, PiezoHapt represents a power-saving solution compared to conventional solutions. Shipments of samples will begin in March 2017.

The actuator can be driven with low voltages of ≤24 V and can produce a wide variety of vibration patterns, depending on the amplitude and frequency of the voltage applied. The new PHUA8060-35A-33-000 type has a footprint of 80 mm x 60 mm (vibration plate). At a frequency of 200 Hz (sine-wave) and a voltage of 24 V peak, the component offers a typical displacement of 55 µm. PiezoHapt is an ideal component for providing haptic feedback to user actions in the displays of smartphones and tablets.

The PiezoHapt actuator is a new addition to the lineup of TDK’s actuators with haptic feedback, which also includes the PowerHap series. Announced in November 2016, PowerHap types feature higher displacement and the highest acceleration and force, all in a single component with integrated sensor functionality, and are suitable especially for applications in vehicles, household appliances, game controllers, industrial equipment and more. With the new PiezoHapt and PowerHap product families, TDK can now provide cutting-edge high-performance haptic solutions for a very wide range of applications.

The PiezoHapt actuator is a new addition to the lineup of TDK’s actuators with haptic feedback, which also includes the PowerHap series. Announced in November 2016, PowerHap types feature higher displacement and the highest acceleration and force, all in a single component with integrated sensor functionality, and are suitable especially for applications in vehicles, household appliances, game controllers, industrial equipment and more. With the new PiezoHapt and PowerHap product families, TDK can now provide cutting-edge high-performance haptic solutions for a very wide range of applications.

Main applications include displays for smartphones and other devices, car navigation systems, touch pads, and controllers. Main features and benefits include low driving voltage of less than or equal to 24 V; thickness of about 0.35 mm, making it one of the thinnest haptic devices in the world; very short response time; and myriad possible vibration patterns.

TDK Corp. is a leading electronics company based in Tokyo, Japan. It was established in 1935 to commercialize ferrite, a key material in electronic and magnetic products. TDK’s portfolio includes electronic components, modules and systems* marketed under the product brands TDK and EPCOS, power supplies, magnetic application products as well as energy devices, flash memory application devices, and others. TDK focuses on demanding markets in the areas of information and communication technology and consumer, automotive and industrial electronics. The company has a network of design and manufacturing locations and sales offices in Asia, Europe, and in North and South America. In fiscal 2016, TDK posted total sales of USD 10.2 billion and employed about 92,000 people worldwide. Download a PDF on the Ultra-thin PiezoHapt actuator here.

Leave a Reply

You must be logged in to post a comment.