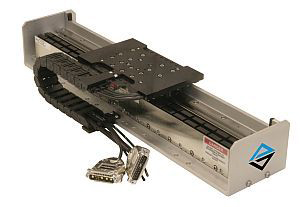

Aerotech (www.aerotech.com) has introduced a high speed, cost-effective linear-servomotor-driven actuator that is more precise than a belt-drive or a ball screw — the ACT Linear Motor Actuator. Unlike belt-drives and ball screws, the high-performing ACT is maintenance free, as it is comprised of non-contact linear motors and encoders.

Since it is a built-in assembled mechanical system, it does away with the guesswork involved in assembling individual parts, making it suitable for various applications, such as pick and place machines, assembly, packaging, electronic assembly and qualification, dispensing, vision inspection, image scanning and processing, life sciences, and inkjet printing.

The ACT is powered by Aerotech’s cog-free linear motors, which enables it to accelerate to five g and achieve a top speed of five m/s. Its rigid mechanical structure reduces settling times while providing outstanding dynamic performance. Providing remarkable system responsiveness, its linear motor has zero friction, no windup and zero backlash, while its magnetic field is self-contained in the U-channel design.

Each ACT actuator features non-contact linear optical encoders that deliver micron-level of repeatabilities. For maximum flexibility, the ACT has also been designed with an amplified sine-wave output or line-driver output encoder. It also comes with optional factory calibration to optimize standard repeatability and accuracy.

The ACT’s flexible design is available with numerous cable management and limit options to meet customer’s specific needs. Meanwhile, a cable management chain is also offered for applications that demand for a complete solution. A bulkhead termination and cable pigtail option is also offered for OEM or applications that demand a user-defined cable management.

Leave a Reply

You must be logged in to post a comment.