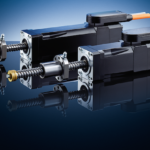

The LinX M-series linear motor features an integrated position sensor with 10 um of resolution, eliminating the need for an external encoder, simplifying system design and reducing overall cost. Modular design of the heatsink and end-caps enables flexibility in system integration. The motor produces a continuous force range of 90 to 160 N and a peak force range of up to 1,200 N.

The series is designed to deliver superior performance for high dynamic applications: velocity up to 10 m/sec and maximum acceleration of higher than 30 G. With integrated position feedback and pneumatics compatible mounting design, the M-Series motor range is a suitable replacement for pneumatic cylinders also simplifying system integration, commission and maintenance. When compared with a pneumatic system the LinX motor offers a reduction in operating costs due to reduced energy consumption and maintenance.

With a fully potted motor body and sealed stainless steel shaft, the motor achieves an IP67 protection level, making it suitable for food and beverage packaging applications.

The LinX motor design itself improves machine life and reduces wear on guide ways or rails, eliminating the downforce associated with flatbed motors due to the zero net attractive forces. The magnets contained within the LinX motor stainless steel cylinder allow machine builders to align the motor with much more ease, meaning machines can be built faster and safer.

The LinX M-series linear motor has been designed in a variety of different sizes to allow for application-specific solutions and will be available in Q1 2019.

For more information, visit www.ancamotion.com.

Leave a Reply

You must be logged in to post a comment.