90% of small U.S. construction companies have safety programs, but only a third have programs to improve the ergonomics of workers’ environments. It’s too bad, because the risk of musculoskeletal disorders (MSDs) is especially high in construction workers. Plus annual wage and salary losses are estimated at $46 million for the U.S. private-construction sector. Workers in other countries don’t fare much better: In the U.K., MSDs cause workers to miss 6.6 million working days a year … with some 469,000 workers suffering from new or long-standing MSDs.

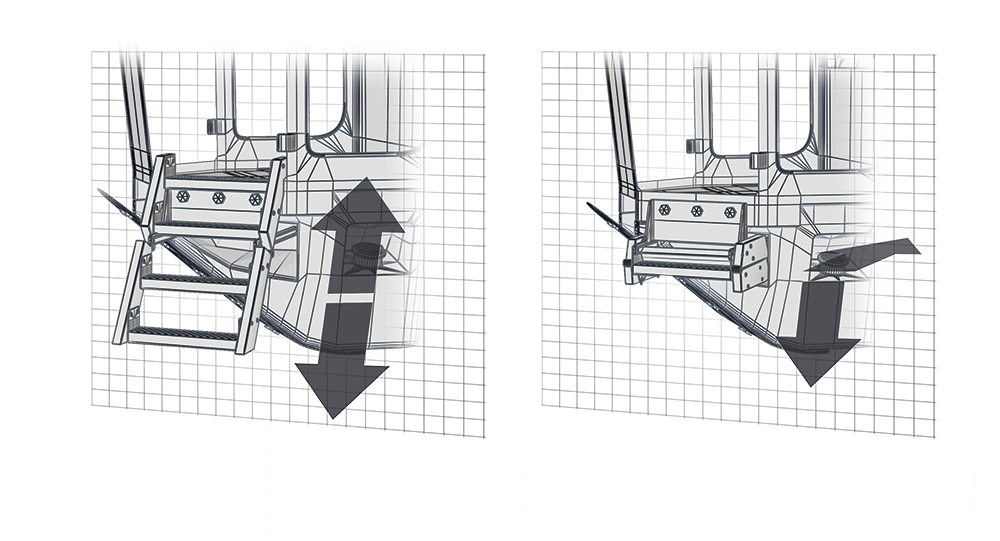

But there is growing interest in implementing ergonomic solutions in today’s construction industry. Relatively simple analysis of heavy-duty off-highway machinery often yields design ideas to improve ergonomics for operators. Case in point: Now in one new design, electric actuators from LINAK on power-adjustable stepladders make it easier and safer for operators to get up into (and out of) elevated cabs on excavators and graders.

Adjustable stepladders and other electrically actuated access systems execute safe extension while bringing step sections closer to ground. That spares drivers’ knees from strain. Because these designs tuck away before the excavator or grader begins moving, they also include steps that are wide, grated for traction, marked for good visibility, and spaced with a rise and run that lets operators use them as a normal stairway. Such a design is far more ergonomic than ladders made of bars flush-mounted to the cab side … which require upper-body strength and balance to use.

Electrically actuated stepladders are powered by a battery with no dependence on any of the off-highway vehicle’s hydraulic systems. That means the ladders are operable even when the main engine isn’t running. Authorized operators simply trigger stepladder action via remote control.

In fact, actuator-operated retractable ladders also serve as a theft and vandalism deterrent, as they make it harder for unauthorized personnel to physically access the higher cabs.

Leave a Reply

You must be logged in to post a comment.