A number of recent advances have improved ballscrew performance, meaning that motion engineers can get more for less.

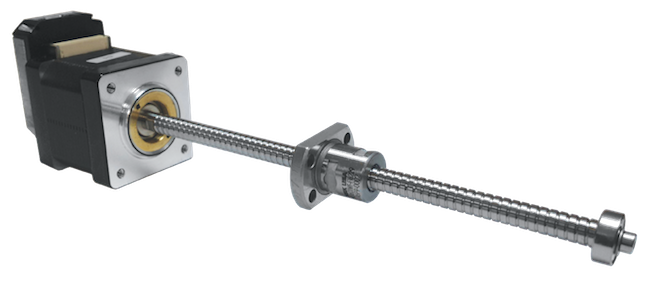

One trend is the continued interest in integrated designs. For instance, ballscrew-based linear actuators are available as all-in-one packages. The benefit is that such integrated packages significantly reduce design time as well as time required for assembling a system and programming the actuator itself.

Another development is that the latest generation of ballscrews has more load density than ever, offering designers higher capacity in a smaller package. Miniaturization is another ongoing trend, as well as faster ballscrews using both rolled and ground screw manufacturing methods.

In fact, according to motion and control manufacturer NSK Americas, precision ground ballscrews have become the preferred choice for precise linear motion because they deliver smooth and accurate movement and give reliable and repeatable results. Linear motion is a common need for all types of advanced equipment and machines; but precise, smooth, reliable, and repeatable linear motion is fundamentally important for several applications within the medical industry.

For example, the demand to reduce the size of linear screw actuators but maintain precision is evident in several medical diagnostic and imaging applications. A diagnostic device, such as a desktop blood analyzer, can process multiple samples at a faster speed and higher accuracy in comparison to its predecessor that was the size of an automobile. Health care practitioners rely on small ballscrew actuators on syringe pumps to accurately dispense precise levels of medication. In imaging applications, such as CT scanners, small actuators position aperture plates to control the X-ray beam. In each of these applications, a leadscrew or ballscrew is combined with a small motor to translate the motor’s rotary motion into linear motion.

In the development of the MBSA Series, NSK Americas replaced the motor output shaft with a journal that is part of the ballscrew shaft. The motor directly rotates the ballscrew shaft which translates the nut for linear motion. This design eliminates the need for a separate motor-to-ballscrew coupling. The MBSA Series allows for a compact space-saving design that reduces system inertia and eliminates alignment error that can occur when the motor and ballscrew are separately mounted.

Leave a Reply

You must be logged in to post a comment.