Although there are more than a dozen symptoms of premature wear and impending failure for V-belts — ranging from visible damage to audible noise — there are a few key ways that these friction-based belts can fail during operation. To help users determine the root cause of a failure or signs of potential failure, V-belt […]

When are stepper motors paired with ball screws (rather than lead screws)?

Stepper motors are widely used in industrial and consumer applications ranging from packaging equipment and medical devices to 3D printers and vending machines. They have excellent torque production at (relatively) low speeds — especially for a given motor size — and offer high-resolution positioning in a simple-to-use format. These benefits make them well-suited to drive lead […]

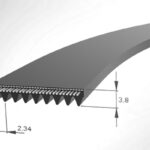

What do the belt section designations H, J, K, L, and M mean for ribbed V-belts?

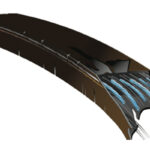

V-belts rely on friction caused by the “wedging” of the belt between pulley flanges — together with internal fiber cords — to transmit power in a wide range of industrial and consumer-goods applications. One variation of the traditional V-belt is the ribbed V-belt — also referred to as a V-ribbed, poly V, or serpentine belt. Ribbed V-belts take […]

The top 10 linear motion articles of 2021

In our 2020 recap of the most-read linear motion articles, we noted how our readers went “back to basics,” with articles about fundamental engineering topics dominating the list. That theme continued in 2021, but this year, the dominant articles dealt not only with engineering basics, but more specifically with “how to calculate” topics. And although […]

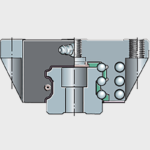

What is a split bridge system and how does it differ from a gantry?

Multi-axis linear systems come in a variety of designs, with Cartesian, gantry, and XY tables being some of the most common types. While these designs simplify construction and can provide space savings, they also introduce “stacking” errors — the compounding of errors from each axis, which manifests at the work piece or tool point. Mounting axes […]

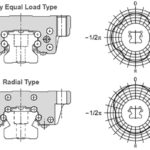

What are the benefits of six-row linear bearings

The most common types of recirculating linear bearings use four rows of balls — two on each side of the bearing block — to provide good load capacity and rigidity. But the four-row design means that when radial (downward or liftoff) or lateral (side) loads are applied, only two rows of balls are engaged to support […]

Contact angle: What is it and how does it affect linear bearing performance?

In profiled rail linear guides that use balls or rollers, the geometry and arrangement of the bearing raceways play a significant role in the bearing’s load capacity, friction, rigidity, and ability to withstand errors in mounting. But there’s another aspect of a bearing’s design that also plays a role in its load capacity and rigidity […]

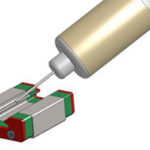

How to choose a lubricant for recirculating linear bearings

All metal-on-metal recirculating bearings require lubrication in order to function properly and provide a reasonable bearing life. Lubrication reduces friction and heat by separating the rolling elements from the bearing raceway, inhibits corrosion, protects bearing surfaces from contamination, and helps seals run smoothly and operate effectively. Although the importance of lubrication is clear, choosing the best […]

Open aperture voice coil stages with 1.20 inch travel and 25.4 micron resolution

Moticont’s HCDS-051-064 series of open aperture voice coil stages are linear DC motor driven stages. Designed for closed loop servo operation, an integral quadrature optical encoder with differential outputs is standard. The stages are clean, quiet, and efficient, with low inertia, high acceleration, and high speed. Each stage has a built-in home switch for accurate […]

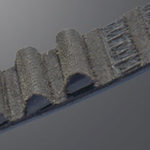

Causes of tooth shear in synchronous belts, and how to avoid it

Synchronous belts transmit power via positive engagement between belt teeth and pulley grooves, making them suitable for applications that require high torque and making them less prone than traditional V-belts to slip in dynamic applications. But even synchronous belts can experience failure if they’re not installed, maintained, and applied properly. One way that toothed belts […]