When sizing a motion system with a ball or lead screw drive, the first step is to determine the screw diameter and lead that can meet the application requirements for thrust force, speed, and compressive (buckling) loads. Once the screw diameter and lead are determined, the next step is to choose a motor that can […]

Ball and lead screw drunkenness: What is it and when does it matter?

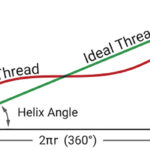

Unlike ball screws, which follow industry standards such as DIN ISO 3408, JIS B1192-1997, or ANSI-B5.48 for accuracy classifications, there are no accuracy standards for lead screws. Instead, many lead screw manufacturers have loosely adopted two of the most common ball screw lead accuracy specifications: lead deviation per 300 mm and lead deviation per revolution. Lead deviation […]

The difference between rack-pinion module and diametral pitch

Gear sizes are typically specified by one of two designations: Module or diametral pitch. While both specifications define the size of the gear teeth, module and diametral pitch are calculated differently, with module (sometimes referred to as metric pitch) being the metric sizing standard and diametrical pitch being the Imperial (inch) sizing method. Standard […]

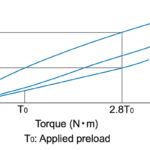

Ball spline preload: How, why, and when it’s applied

Like other linear motion components where rolling elements ride in raceways, ball splines can be supplied with preload. In the case of a ball spline, the main purpose of preload is to reduce angular backlash — clearance in the rotational direction — when torque is applied. Without preload, ball splines have a small amount of […]

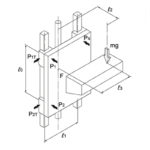

What’s the difference between moment and torque in linear motion applications?

In linear motion, we often deal with applications that involve forces applied at a distance from a linear guide — referred to as cantilevered, or moment, loads. In these cases, we’re concerned with guide’s moment load capacity, or its ability to resist rotating. But we also deal with components that should rotate when a force […]

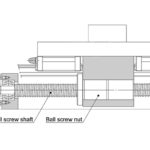

What is ball screw whip and why does it happen?

Ball screws are often the drive mechanism of choice in applications that require high thrust forces with excellent positioning accuracy and repeatability. But one of the drawbacks of ball screw technology is that speed is inversely related to length — the longer the ball screw shaft, the more likely it is to whip, like a […]

What is a 7th axis (also known as an RTU) and when is it used?

Linear Cartesian and gantry robots are used extensively in automation, particularly for tasks such as pick and place and assembly. But for applications that require movements such as changing the orientation of a part or navigating around complex obstacles, the robot of choice is often the 6-axis articulated robot. Despite their dexterity, the reach of a […]

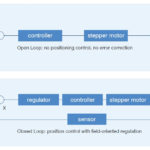

When does open-loop stepper control still make sense?

Stepper motors are inherently open-loop devices, able to make precise moves without feedback regarding motor position. But one of the drawbacks of using stepper motors in some applications is that if steps are lost (or gained), the system has no way to detect this. The resulting discrepancy between the actual position of the motor and […]

The benefits – and drawbacks – of linear motors for dynamic applications

Linear motors can achieve high acceleration rates and long travel lengths with good thrust forces and extremely high positioning accuracies, while other drive mechanisms, such as belts, screws, or rack and pinions, must sacrifice at least one of these requirements in order to achieve the others. This is why linear motors are the preferred choice for […]

What’s the difference between a vertical lift stage and a Z axis actuator?

In many applications that require vertical motion, a Z axis actuator is combined with one or two horizontal axes in a Cartesian or gantry-style arrangement. In these multi-axis configurations, the moved load is mounted to the Z axis via a bracket, creating a moment load that affects not only the Z axis, but also the horizontal […]