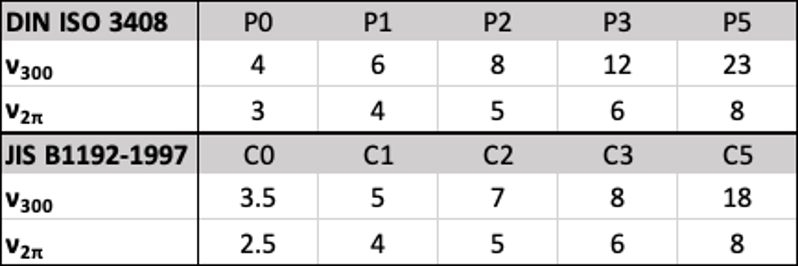

Unlike ball screws, which follow industry standards such as DIN ISO 3408, JIS B1192-1997, or ANSI-B5.48 for accuracy classifications, there are no accuracy standards for lead screws. Instead, many lead screw manufacturers have loosely adopted two of the most common ball screw lead accuracy specifications: lead deviation per 300 mm and lead deviation per revolution.

Lead deviation per 300 mm

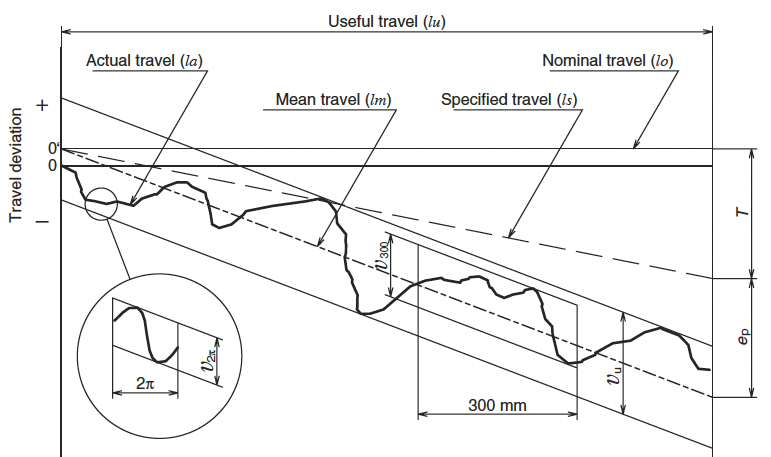

Lead deviation per 300 mm defines the maximum range of travel deviation (peak-to-valley) over any 300 mm section of the useful screw length. In the DIN ISO and JIS standards for ball screws, this specification is denoted as ν300, while the ANSI ball screw standard refers to it as maximum rate error.

In the absence of a standard to govern lead screw accuracy, many lead screw manufacturers use a version of the “lead deviation per 300 mm” specification, although the reference travel distance may be less than 300 mm. (Some lead screw manufacturers specify lead deviation over a distance as short as 25 mm.)

Image credit: NSK

Lead deviation per revolution

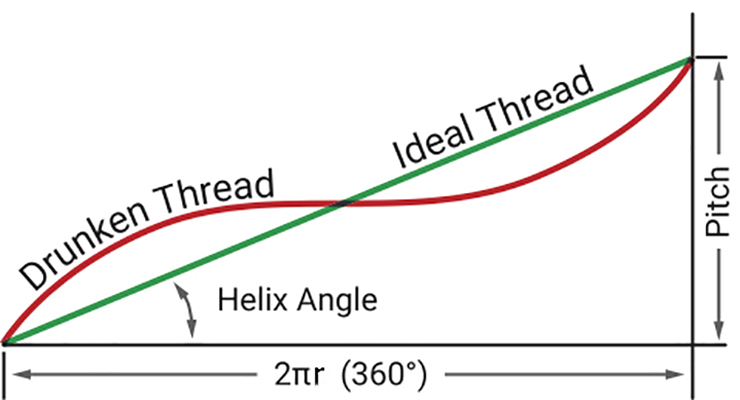

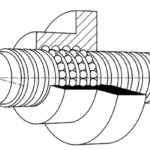

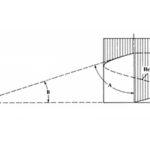

A power transmission screw translates rotary motion to linear motion through a helix formed around the screw shaft. When “unwrapped” from the screw shaft, the ideal helix thread will form a straight line that serves as the hypotenuse of a right triangle, with the other two sides being the circumference of the screw and the pitch, or lead, of the screw. However, variations in the thread helix will cause it to produce a curved line when unwrapped. This curvature of the helix represents erratic motion of the screw with individual each rotation.

In DIN ISO and JIS standards, this travel deviation within one revolution of the screw is defined by the specification ν2π, whereas the ASTM standard refers to this specification as wobble error.

Lead screw manufacturers typically refer to this travel deviation per revolution as screw drunkenness.

Although lead deviation per 300 mm (ν300) is the most commonly used accuracy specification for ball and lead screws, if the application has a very short travel distance, or if the travel deviation per revolution is critical — such as very short stroke pipetting or pumping applications — users should consider the screw drunkenness, or ν2π specification, when sizing or selecting a suitable screw assembly.

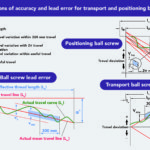

Positioning versus transport ball screws

The DIN ISO and JIS standards classify ball screws as one of two types: positioning or transport. Positioning screws are denoted with the letter “P” by DIN ISO, and with the letter “C” by JIS. Transport screws are denoted with the letter “T” by DIN ISO, and with the letters “Ct” by JIS.

Each type of ball screw — positioning or transport — is further broken down into numerical accuracy grades, with lower numbers indicating higher (better) accuracy. For example, P3 and T5 are both DIN ISO accuracy classes (with P3 being higher, or better, accuracy than T5), while C1 and Ct7 are JIS accuracy classes (with C1 being higher, or better, accuracy than Ct7).

The ν300 lead accuracy specification applies to both positioning and transport screws, although there are slight differences between the ν300 values for DIN ISO versus JIS versions. However, lead deviation per revolution, ν2π, is only defined for positioning screws.

Leave a Reply

You must be logged in to post a comment.