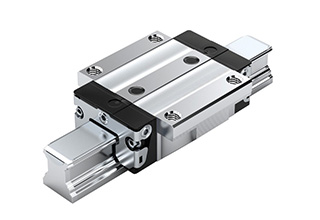

The patented entry zone of the new BSHP ball runner blocks from Rexroth improves travel accuracy and work piece quality while greatly increasing load capacities and service life. These runner blocks are available in most sizes, versions, and accuracy classes. BSHP ball runner blocks are 100% interchangeable into existing profiled rail applications using the same part number as before.

The new BSHP runner blocks distinguish themselves from the previous generation by reducing pulsation when placed under a load. The machining quality and accuracy of cutting machine tools, measuring machines, glass machining equipment and other tooling benefit as a result of reduced pulsation.

Rexroth has also boosted dynamic load capacities by approximately 26 percent with static load capacities improving by as much as 50 percent. Dynamic load capacities form the basis for service life calculations. The higher dynamic values lead to a service life that is up to 200 percent longer. Higher load capacities also promote energy-efficient lightweight construction for new machine concepts as the new runner blocks can allow machine manufacturers to use a smaller size than before without sacrificing performance. Downsizing saves weight, installation space and money.

Advancements in travel accuracy and reduced fluctuation in friction force are realized by Rexroth’s patented entry zone in the ball runner block. The steel inserts elastically adapt to the operating load so that the balls can enter the entry zone smoothly, without any pulse-like stresses. The entry zone individually adapts to the current operating load of the ball runner block.

The new BSHP ball rail runner blocks also align with Rexroth’s interchangeable design, whereby users can combine the runner block and profiled rails of identical sizes as required. This reduces logistics, assembly and servicing outlay throughout the entire lifecycle. The new BSHP runner blocks in sizes 15 to 65 are 100 percent interchangeable into existing profiled rail applications using the same part number as before.

For more information, visit the Bosch Rexroth Profiled Rail website.

Leave a Reply

You must be logged in to post a comment.