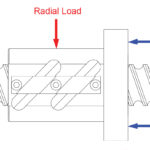

The most common types of recirculating linear bearings use four rows of balls — two on each side of the bearing block — to provide good load capacity and rigidity. But the four-row design means that when radial (downward or liftoff) or lateral (side) loads are applied, only two rows of balls are engaged to support the load, and when the load is oriented at 45 degrees to the bearing block, only one row of balls provides support.

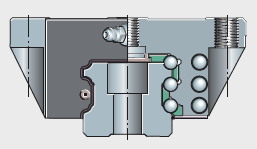

Although four-row linear bearings are widely used in applications ranging from dispensing to pick-and-place and transport, applications such as machine tools and presses often call for very high load capacity and rigidity, but also need to keep the linear guide footprint reasonable and to keep friction as low as practical. To meet this requirement, some manufacturers have designed six-row linear bearings, with three rows of balls on each side of the bearing block.

Image credit: Schaeffler

Six-row linear bearing designs

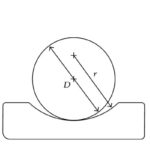

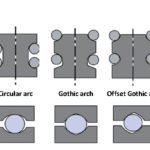

The raceway geometry — circular arc or Gothic arch — of a profiled rail bearing plays a significant role in its stiffness, friction, and load capacity. With this in mind, manufacturers of six-row linear bearings take one of two approaches to raceway geometry.

One six-row linear bearing design uses circular arc contact for all six rows of balls.

Circular arc geometry is characterized by two contact points for each ball, so differential slip and friction are lower than with other geometries. And using a low-friction geometry helps to minimize the increase in friction due to the two additional rows of balls.

Circular arc geometry also allows different contact angles between the balls and raceways. For example, a common design uses a 45 degree contact angle for the top and bottom rows of balls to distribute the load equally, and a 60 degree contact angle for the middle rows of balls to further improve load capacity.

Image credit: Schaeffler

In this design, the top and middle rows of balls provide support for downward loads, while the two middle rows of ball provide support for lift-off loads. And for lateral (side) loads, all six rows of balls provide support.

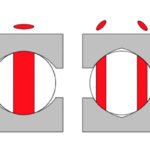

Another approach to the six-row linear bearing design uses two-point circular arc contact for the top and bottom rows, while the middle rows have four-point Gothic arch contact.

Gothic arch geometry provides high rigidity but also higher friction, so by using Gothic arch geometry only on the middle rows, these bearings take advantage of the increased rigidity without the significant increase in friction that would result if all six raceways were designed with Gothic arch geometry.

Image credit: NSK

In this design, each row of balls uses a 45 degree contact angle, which equally distributes the load among four rows of balls, regardless of loading direction. This six-row linear bearing design also enables the bearing to withstand higher shock loads than four-row designs.

Leave a Reply

You must be logged in to post a comment.