BRECOflex CO. is launching a new timing belt. It’s the company’s most innovative timing belt to hit the market since its move-series in 2014. It’s called BRECOroll.

BRECOflex CO. is launching a new timing belt. It’s the company’s most innovative timing belt to hit the market since its move-series in 2014. It’s called BRECOroll.

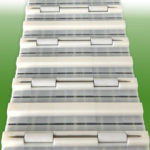

Typically, toothed timing belts used for material handling tasks are very long. The belt’s load side usually lies in a support rail which causes friction. BRECOroll provides the solution for slider bed friction. This new innovation has rollers integrated into the belt teeth. These rollers replace the sliding friction with rolling friction resulting in less stress on the belt and the motor.

BRECOroll advantages include:

• Longer belt life because of reduced friction and heat

• Smaller motor possible due to reduced friction forces

• Overall reduced energy consumption

• Cost savings on downtime for belt replacement and drive maintenance

• Load bearing capacity of 6kg/tooth (13.2lbs/tooth)

• Can accommodate backings and profiles (cleats)

With the demand for consumer products and manufacturing at an all-time high, it is more important than ever to have the most efficient material handling systems in place. Since BRECOroll is a brand new product, BRECOflex CO.., L.L.C. is “rolling out” 100 mm wide T20 for the launch since it is a common timing belts size for many material handling applications. They are encouraging customers who currently purchase this width and pitch to give BRECOroll a try. The introductory price will be the same as the standard T20 price for those willing to offer details of their application and provide feedback about their product experience.

BRECOflex

www.brecoflex.com

Leave a Reply

You must be logged in to post a comment.