In part 1 of this series on bearing speed, we looked at the factors that limit the speed of linear recirculating bearings. In this segment, we’ll look at the factors that limit the speed of linear plain bearings. Linear plain bearings operate with sliding contact between the two bearing surfaces, so the limitations encountered with […]

FAQs + basics

Podcast: Scott of Nippon on iron core, U-channel, and tubular linear motors

In a recent Technology Tuesdays podcast, Brian Scott, application engineer at Nippon Pulse America, talked to me a little bit about linear motors including iron core, U-channel, and tubular linear motors … and the benefits and drawbacks of each. He also shed some light on the major design objectives OEMs cite when migrating axes to linear motors. Click here […]

What limits linear bearing speed? (Part 1)

High-speed motion is a requirement for applications where throughput is a critical factor, such as packaging and electronic assembly. These systems typically use linear motors or steel reinforced belt drives in conjunction with recirculating linear bearing guides for good stiffness and high load capacity. But the speeds demanded by these applications can pose a challenge […]

Have a ball screw application? Check out these resources for sizing and selection

One of the most popular subjects on this site is ball screws—especially the topic of how (and when) to select a ball screw. This is not surprising, because screws, and ball screws in particular, are workhorses of linear motion, with a range of styles, sizes, and performance capabilities that covers just about any application an engineer or designer […]

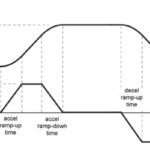

How to reduce jerk in linear motion systems

The most common move profiles for linear motion systems are trapezoidal and triangular. In a trapezoidal move profile, the system accelerates from zero to its maximum speed, travels at that speed for a specified time (or distance), and then decelerates to zero. Conversely, the triangular move profile accelerates from zero to maximum speed and then […]

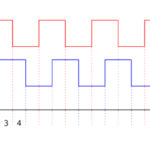

What is quadrature encoding?

As an incremental encoder turns (or travels linearly, in the case of a linear encoder), it generates a precise number of equally spaced, square wave pulses. The number of pulses generated for each rotation (or unit of linear distance) determines the encoder’s resolution. For rotary encoders, resolution is expressed in terms of pulses per revolution […]

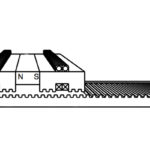

What are linear stepper motors?

Like most linear motors, a linear stepper motor is essentially a variation of the rotary design, cut radially and laid out flat. Similar to their rotary counterparts in operation and performance, linear stepper motors are typically run as open-loop systems and are capable of providing high resolution at high speeds and accelerations. The linear stepper motor almost exclusively […]

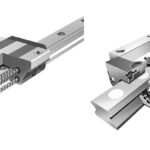

Which linear guides are interchangeable?

The need to replace a linear guide in an existing machine or assembly can arise for any number of reasons: to improve the stiffness of the assembly by changing to a bearing with higher preload, or to accommodate unforeseen space constraints by using a different bearing type or style. And sometimes, a linear guide needs to be replaced […]

What are recirculating linear bearings?

Linear ball and roller bearings can be broadly divided into two categories—recirculating and non-recirculating—depending on whether or not the rolling elements actually flow (or circulate) through the bearing housing. In order to understand what a recirculating linear bearing is, let’s first take a look at bearings that don’t recirculate. Non-recirculating linear bearings Non-recirculating bearings have […]

Why use linear-induction motors — and could they drive Hyperloops one day?

Contributed FAQ courtesy H2W Technologies || Linear-induction motors work in applications that require rapid movement of large payloads. Linear-induction motors can output speeds to 1,800 in. per second (45 m/sec) or more … … and accelerations from 3 to 4 g. Standard LIMs can produce forces in the range of 720 lb (3,200 N) at a 3% duty cycle. […]