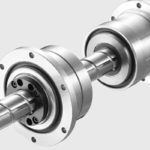

A ball screw spline is a combination of two components — a ball screw and a rotary ball spline. By combining a driving element (the ball screw) and a guiding element (the rotary ball spline), a ball screw spline can provide both linear and rotary motion, as well as spiral motion, in a highly rigid, […]

Ball + leadscrew driven

How to pick the right drive screw

Choosing the correct drive screw type is critical to getting the best actuator performance, accuracy, and repeatability. Chris Maupin • Program Manager and Engineer | Hunt Valve Actuator Division Screw drivetrains are the most common types of electromechanical linear actuators. A screw drivetrain acts as a linear force generation system, converting a rotary torque input […]

ElectroCraft expands AxialPower family of linear actuators with the APES 17

ElectroCraft has recently expanded the AxialPower enhanced series of linear actuators to include a new high-performance 42mm (NEMA 17) frame size. This new linear actuator is highly configurable and: • Is available with a variety of imperial or metric leadscrew options • Achieves resolutions of 0.006 mm to 0.050 mm per step • Delivers output […]

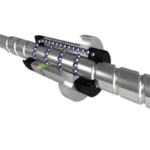

THK adds high-speed SDA-V/SDAN-V caged ball screws to linear motion offerings

THK’s new Type SDA-V/SDAN-V caged ball screw is engineered to enable the development of high-speed machine designs. Featuring newly developed circulation components, the Type SDA-V/SDAN-V picks up balls in the tangential direction and achieves a maximum rotational speed of 5,000 rpm — for a maximum DN value of 160,000. Torque remains stable even during long […]

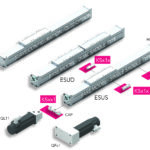

PHD Inc. now sells Series ESU-RB ballscrew linear actuators

PHD Inc. now sells a new Series ESU electric actuator — the ESU-RB. This linear actuator incorporates a ballscrew and features a robust enclosed design with a high capacity rail-bearing system. These features let the actuator deliver exceptional moment and load capability. The ESU-RB electric actuator is available in three sizes with travels lengths up […]

Linear motion in medical applications: Linear actuators in patient lifts, beds, and tables

Moving a patient in a hospital or medical facility doesn’t always involve racing down a hallway with the patient in a wheelchair or on a gurney. Very often, a patient simply needs to be moved from a lying or sitting position to a standing position (or vice-versa). Even for patients who possess some degree of […]

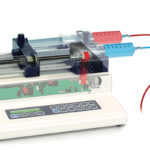

Linear motion in medical applications: Lead screw driven syringe pumps

When we think of syringes, we typically think about the single-use type that doctors and nurses use to administer vaccines or individual doses of medication. But some conditions necessitate frequent or constant doses of critical medication, making it undesirable or even unfeasible to administer via single-use syringes. And in other cases, medications that would normally […]

High load capacity actuator from NB Corporation

This compact single axis actuator from NB Corporation features a unique “U” shaped integrated slide guide and ball screw. The BG actuator’s highly rigid structure may be one-end supported. The 4 ball circuits contained in its slide block deliver high load capacity, accuracy and rigidity. The product catalog supplies all dimensions, drawings and ratings necessary […]

New tools, services aid ball screw selection and design

Ball screw performance continues to improve, thanks to advancements in manufacturing methods and materials. Newer generations of ball screws have higher load capacities, which means they’re increasingly being used for applications with higher loads as well as more challenging environmental conditions. Hence, the rise in ball-screw-driven actuators replacing traditional fluid power actuation methods in some […]

What options are there for integrated motor and screw designs?

Ball and lead screw assemblies are often driven by a motor connected in-line with the screw shaft via a coupling. While this mounting arrangement is simple and easy to service, the addition of a non-rigid mechanical component (the coupling) can introduce windup, backlash, and hysteresis — all of which affect positioning accuracy and repeatability. The […]