Choosing the correct drive screw type is critical to getting the best actuator performance, accuracy, and repeatability. Chris Maupin • Program Manager and Engineer | Hunt Valve Actuator Division Screw drivetrains are the most common types of electromechanical linear actuators. A screw drivetrain acts as a linear force generation system, converting a rotary torque input […]

Ball + lead + roller screws

How to protect ball screws in harsh environments

Harsh environments can wreak havoc on motion system components — especially rolling element systems such as linear guides and ball screws. And while protective devices such as rail covers, wipers, and scrapers are widely available for linear guides, protecting ball screws in harsh environments is a bit more tricky. But despite being more difficult to […]

What are fixed and floating bearings in the context of linear motion?

There are two instances when the terms “fixed bearing” and “floating bearing” are used in linear motion: to describe the support bearings used on ball and lead screws, and to describe linear guides mounted in parallel. And while the meanings of the terms are the same in both situations, their applications are different in each […]

THK adds high-speed SDA-V/SDAN-V caged ball screws to linear motion offerings

THK’s new Type SDA-V/SDAN-V caged ball screw is engineered to enable the development of high-speed machine designs. Featuring newly developed circulation components, the Type SDA-V/SDAN-V picks up balls in the tangential direction and achieves a maximum rotational speed of 5,000 rpm — for a maximum DN value of 160,000. Torque remains stable even during long […]

How to account for shock and vibration loads in ball screw drives

Calculations of ball screw service life and permissible static load take into account loads and forces that are predictable and quantifiable — thrust loads due to acceleration, process forces, and forces generated when holding a load in place, for example. But some applications are also susceptible to loads caused by shock and vibration — loads […]

Tolomatic expands hydraulic-class electric actuator force range to 50,000 lbf

Tolomatic’s expanded extreme-force electric actuator family now includes the RSX128 actuator, rated up to 50,000 pounds of force (222.4 kN). Ideal for replacing hydraulic cylinders and designed for 100 percent duty cycle, the RSX actuator features Tolomatic’s precision-ground planetary roller screws for long, consistent operating life in challenging environments. Applications include assembly, automotive manufacturing, timber […]

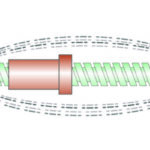

What are differential roller screws and how do they differ from planetary designs?

Traditional roller screws — sometimes referred to as planetary roller screws — can produce axial forces comparable to hydraulic cylinders, with the speed and precision capabilities of ball screws, at a price point that falls between the two. A variation of the planetary roller screw — referred to as a differential roller screw — reduces some […]

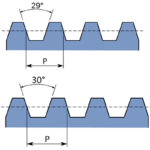

Acme or trapezoidal? What’s the difference between lead screw designs?

In power transmission applications, there are two primary types of screw drives: those that use recirculating balls or rollers, for applications that require high rigidity, excellent positioning accuracy, and high duty cycles, and those that rely on sliding contact, for applications that require corrosion-resistance, self-locking operation, and customizable nut designs. The second category — screw […]

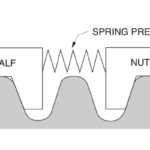

How can lead screw backlash be reduced?

Backlash is an inherent property of lead screw assemblies due to the sliding motion between the screw and the nut. For some applications, a certain amount of backlash, or “play,” can be tolerated, but applications such as positioning, dispensing, or assembly often require a level of precision and repeatability that can’t be achieved if backlash […]

What’s the difference between ball screw critical speed and characteristic speed?

Ball screw drives incorporate two primary moving components: the rotating screw shaft and the nut that traverses the screw. (The radial bearings that support the screw shaft play a minor role for the purposes of this discussion.) This means that to accurately determine the maximum allowable speed of a ball screw assembly, there are two […]