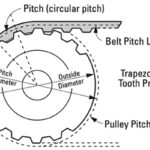

When designing a belt drive system, the first step is to choose the most suitable belt for the application. But the pulleys also play an important role in the performance of the belt — especially in synchronous belt drive systems, where proper meshing of the belt teeth with the pulley grooves can affect everything from […]

Belt + chain drives for linear

Synchronous belt materials: What’s the difference between urethane and neoprene?

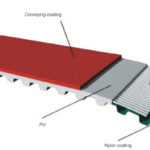

Synchronous belts for linear motion applications — such as general transport conveyors or high-speed gantry positioning — are available in a wide range of materials suitable for virtually any application. The most common synchronous belt materials are neoprene and polyurethane, but specialty materials and backing surfaces are also available to address requirements such as temperature extremes, […]

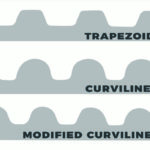

What’s the best timing belt tooth profile for high-speed applications?

Synchronous belts (also referred to as timing belts) are used in a wide range of power transmission and transport applications that require good positioning accuracy. Tensile cords molded into the belt material help eliminate or minimize belt stretch, and positive engagement between the teeth of the belt and the pulley make synchronous belts less likely […]

What causes synchronous belt noise and how can it be reduced?

Synchronous belts are common in motion systems, providing smoother operation and better high-speed performance than chains and lacking the problems of slipping and stretching that can plague V-belts in precision applications. But one downfall of synchronous, or toothed, belts is the noise they produce. Although quieter than a chain drive, a synchronous belt can still generate noise […]

When to consider Kevlar reinforced belts for linear motion applications

Both types of belts commonly used in linear positioning applications — V-belts and synchronous designs — have internal tensile cords that serve as the primary load-carrying component. Or, as one engineer from Gates Mectrol put it, the tensile cords are the “muscle” of the belt. V-belts and synchronous belts are offered with tensile cords of various materials, including polyester, […]

How to calculate motor drive torque for belt and pulley systems

Belt driven linear systems are common in applications that require long travel and high speed, such as gantry robots and material handling and transport. The motors of choice for these systems are often servo motors, for their ability to accurately control position, speed, and torque. Sizing and selecting the servo motor requires determining both the continuous […]

igus unveils new quick-fill energy chain

The new E4Q energy chain from igus can be opened and closed in seconds without tools and has been specifically developed for the special requirements of unsupported lengths and long travels. igus, the Germany-based manufacturer of motion plastics, unveiled a prototype of the new E4Q in April at Hannover Messe. The chain links have a […]

How to measure synchronous (toothed) belt tension

Updated June 2019 || One of the benefits of synchronous belts is their ability to operate with lower tension than their V-belt counterparts. And once the proper tension is determined and applied, synchronous belts rarely need re-tensioning. But improper tension in a synchronous belt drive system — either too low or too high — can […]

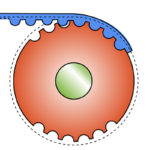

When do synchronous belts need flanged pulleys?

Synchronous belts transmit power via positive engagement between profiled teeth on the belt and pulley. Although this tooth engagement (along with proper belt tension) prevents the belt from ratcheting, the belt is free to track, or move side-to-side, on the pulley. To prevent the belt from riding off the pulley, and to resist the lateral […]

U.S. Tsubaki Power Transmission now offers Super Stainless roller chain for power transmission

Challenging automation and motion applications need tough chain — such as Super Stainless roller chain. In the past, design engineers had to choose between the corrosion resistance of stainless steel and the strength of carbon steel. Now U.S. Tsubaki offers a single chain that offers both corrosion resistance and strength. With its Super Stainless chain, […]