Servo- and stepper-driven electrical linear actuators are an efficient and economical way to provide accurate motion control for a wide variety of machine applications. Chip McDaniel AutomationDirect When it comes to automated machinery, there’s no doubt that observing a high-speed robotic arm zoom through intricate movements can be impressive. But although the price and complexity […]

Linear drives (all)

Update on today’s belt drives

Belt drives have continued to evolve with new applications. Industrial belt drives in motion designs consist of rubber, engineered plastic, metal, or (most common) multi-material belts that wrap around drive pulleys — grooved or otherwise profiled wheels mounted on a shaft — in turn driven by electric motors. Powered by various motor types, belt drives run […]

Compact linear motion system brings modularity to small-space applications

Thomson Industries, Inc. has introduced a family of compact linear systems that makes it easier for motion designers to implement complex applications in small spaces. Designers needing thrust and bearing support in a single, compact unit now have the flexibility to build such applications with versatile, time-tested components from Thomson. “As demand for smaller-scale applications […]

Miniature lead screws for compact application designs

Thomson Industries, Inc., has introduced a line of miniature lead screws and nuts. This new offering extends the Thomson lead screw product line to include 2-, 3- and 4-millimeter diameters. “OEMs are increasingly demanding components for smaller assemblies, and we are pleased to announce that Thomson high-quality lead screws and nuts are now available in […]

Rediscovering ball splines for robust linear and rotary motion

Ball splines were once a staple for machine designers seeking an elegant way to integrate rotary and linear motion. Driven by pressures to speed their machines to market, many designers found it faster to implement prepackaged solutions in which rotary and linear motion shafts had already been integrated. By Charles Isaac • Thomson Industries Chris […]

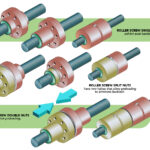

How to choose a roller screw nut assembly

Updated August 2023 • A roller screw’s application will dictate whether the shaft or nut should rotate. In either case, the type of nut selected depends on the load and how the assembly will move and actuate the system. There are three major types of roller screw nuts: Single, split, and double. Single nuts are […]

Precision ball splines deliver robust rotary and linear motion integration

Thomson Industries, Inc., has introduced a line of precision ball splines that enable robust delivery of rotary and linear motion on a single shaft. These new components give designers more flexibility to compress an assembly, extend a stroke, distribute a load or otherwise meet modern automation demands. “Ball splines have provided an elegant, single shaft […]

How to select the right roller screw size

Roller screw systems typically have smaller footprints and more compact designs than their hydraulic counterparts. One motivation to replace hydraulics with roller screws is to reduce bulky and auxiliary equipment and its associated maintenance without compromising performance. Roller screw shafts come in a variety of diameters and load capacities. Some are 3.5 mm in diameter with […]

igus offers custom toothed belt pulleys delivered in 48 hours

igus is expanding its 3D-print and online ordering offering to include custom format toothed belt pulleys. Toothed belt pulleys are a common component in many machines and are widely used in linear drives of printers, robots, and packaging machines. However, if an individual variant is required, developing a custom component can take days or even […]

Lead-screw assemblies from igus for automotive applications

igus’ dryspin lead-screw assemblies are now available as a single-source solution for the automotive industry. In today’s vehicles, advanced linear motion components play a critical role in providing convenience and safety to drivers. Lead-screw assemblies are used extensively wherever automotive parts need to be opened, closed, lifted, or lowered. Typical uses include seats, doors, sunroofs, […]