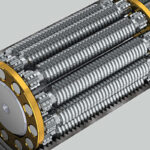

Bosch Rexroth’s electromechanical cylinders (EMCs) are now available in a high-force, high-precision, low-maintenance version – the EMC-HP. Designed for heavy loads up to 100 kN, the new actuators are robust, compact and low-maintenance. Based on the reliable planetary screw drive, users will benefit from impressive continuous power even under harsh conditions. This is thanks to […]

Linear drives (all)

Self-lubricating toothed belt axis for clean use in food manufacturing

igus has introduced a maintenance-free toothed belt axis specifically designed to improve sanitation in food manufacturing systems. The new drylin ZLW toothed belt axis is based on hygienic design principles and uses FDA-compliant materials. Cleaning complex machines and systems in food production leads to longer and therefore expensive downtime. For instance, industrial bakeries are faced […]

What is a high helix (high lead) screw?

Ball and lead screws are specified by the diameter of the screw shaft and the lead (or, in some cases, pitch) of the screw thread. The lead, which specifies how far the nut travels for each revolution of the screw, is created by the thread, or helix, that wraps around the screw shaft. If the […]

Rollon’s updated digital platform includes personalized product selector

Rollon, a leading manufacturer of linear motion systems, guides, linear actuators and gantry systems, has unveiled a new digital tool to help engineers design equipment and systems more efficiently. The new ecosystem consists of two core elements: a redesigned corporate website and myRollon — a tool that personalizes product selection. The website has been expanded […]

How to calculate duty cycle and what it means for machine life

Determining the life of a linear system that uses balls or rollers is relatively straightforward, thanks to the L10 bearing life equation, which gives life in meters of travel (for linear bearings) or revolutions (for screws). And for plain bearings and lead screws, manufacturers typically use the bearing’s PV value and operating conditions to provide an […]

Screw drives see new uses in robotics, other applications

Some of the surest, time-tested methods of linear actuation are screw drives. Whether lead- or ball- or roller screws, screw actuation remains a large part of the linear actuation equation, thanks to their reliability, accuracy, and relative simplicity of operation. Recently screw drive developments have included advances in materials as well as manufacturing methods leading […]

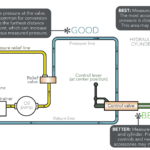

Part 2 of 2: Electric actuators as an alternative to hydraulic cylinders

Here we offer some tips for converting a fluid-power-driven axis to electrical actuation. By Ryan Klemetson • Business Development Manager | Tolomatic, Inc. As explained in Part 1 of this article series on motioncontroltips.com, hydraulic systems offer long service life, but they’re not as efficient as electric systems. Electric systems also provide precise position, velocity, […]

What is an inverted roller screw and how does it work?

Roller screws are often thought of as the standard planetary design, but several variations exist, including differential, recirculating, and inverted versions. Each design offers unique benefits in performance capabilities — load capacity, torque, and positioning — but the inverted roller screw’s primary strength is its ability to be easily integrated into actuators and other subassemblies. Recall that […]

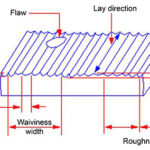

Linear bearing basics: Surface roughness, texture, and finish

One of the factors to consider when selecting shafts for linear bearings is surface roughness, which describes the microscopic asperities, or peaks, and valleys present on a material’s surface. But surface roughness is an important specification for all types of linear guides and screws — whether plain or recirculating, round shaft or profiled rail, ball […]

Screw handedness: When do you need a left-handed screw?

Just like people, ball and lead screws can be either right-handed or left-handed. But in screw terminology, handedness indicates the direction in which the nut moves relative to the direction of the screw’s rotation. By far the most common version is the right-handed screw, in which the nut moves toward you when the screw is […]