Pneumatics (and compressed air) are indispensable in many industrial applications. They’re cost-effective and easy-to-understand technologies that are rugged enough to run in even very challenging environments. The problem is that some facilities can spend up to 30% of their electricity bill on generating compressed air. Because pneumatic actuators for linear motion (which have been an […]

Linear drives (all)

THK adds high-speed SDA-V/SDAN-V caged ball screws to linear motion offerings

THK’s new Type SDA-V/SDAN-V caged ball screw is engineered to enable the development of high-speed machine designs. Featuring newly developed circulation components, the Type SDA-V/SDAN-V picks up balls in the tangential direction and achieves a maximum rotational speed of 5,000 rpm — for a maximum DN value of 160,000. Torque remains stable even during long […]

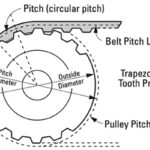

How to specify pulleys for synchronous belt drives

When designing a belt drive system, the first step is to choose the most suitable belt for the application. But the pulleys also play an important role in the performance of the belt — especially in synchronous belt drive systems, where proper meshing of the belt teeth with the pulley grooves can affect everything from […]

How to account for shock and vibration loads in ball screw drives

Calculations of ball screw service life and permissible static load take into account loads and forces that are predictable and quantifiable — thrust loads due to acceleration, process forces, and forces generated when holding a load in place, for example. But some applications are also susceptible to loads caused by shock and vibration — loads […]

Tolomatic expands hydraulic-class electric actuator force range to 50,000 lbf

Tolomatic’s expanded extreme-force electric actuator family now includes the RSX128 actuator, rated up to 50,000 pounds of force (222.4 kN). Ideal for replacing hydraulic cylinders and designed for 100 percent duty cycle, the RSX actuator features Tolomatic’s precision-ground planetary roller screws for long, consistent operating life in challenging environments. Applications include assembly, automotive manufacturing, timber […]

Linear guides, power transmission, actuators see unexpected applications

Our 2020 survey of the industry indicates an unabated trend towards more automation of previously static or manually tended systems. Key to these new offerings is installation simplicity for OEMs and end users of linear components for linear axes … as well as positioning stages and Cartesian robots. In fact, Cartesian robots (also called linear […]

What are differential roller screws and how do they differ from planetary designs?

Traditional roller screws — sometimes referred to as planetary roller screws — can produce axial forces comparable to hydraulic cylinders, with the speed and precision capabilities of ball screws, at a price point that falls between the two. A variation of the planetary roller screw — referred to as a differential roller screw — reduces some […]

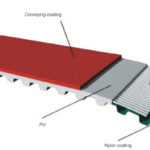

Synchronous belt materials: What’s the difference between urethane and neoprene?

Synchronous belts for linear motion applications — such as general transport conveyors or high-speed gantry positioning — are available in a wide range of materials suitable for virtually any application. The most common synchronous belt materials are neoprene and polyurethane, but specialty materials and backing surfaces are also available to address requirements such as temperature extremes, […]

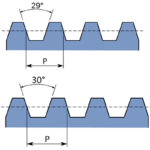

Acme or trapezoidal? What’s the difference between lead screw designs?

In power transmission applications, there are two primary types of screw drives: those that use recirculating balls or rollers, for applications that require high rigidity, excellent positioning accuracy, and high duty cycles, and those that rely on sliding contact, for applications that require corrosion-resistance, self-locking operation, and customizable nut designs. The second category — screw […]

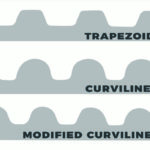

What’s the best timing belt tooth profile for high-speed applications?

Synchronous belts (also referred to as timing belts) are used in a wide range of power transmission and transport applications that require good positioning accuracy. Tensile cords molded into the belt material help eliminate or minimize belt stretch, and positive engagement between the teeth of the belt and the pulley make synchronous belts less likely […]