Corrosive environments can include anything from detergents and chemicals for washdown (the high-pressure cleaning of equipment), to acid baths and their related vapors, to chemicals in food processing. Because profiled linear rails, round shafts, and ball screws are made primarily from steel components, they’re highly susceptible to corrosive agents, which can quickly cause rust, pitting, […]

Ball + roller guides

What are miniature profiled rails?

Updated 2021 ⚙️ As we explain in this article, miniature rails are more than just smaller versions of standard profiled rails. Profiled rails have high load-carrying capacity for their size. But when smooth, precise motion is needed and the load being moved is not very high, they can be overkill for the application. That’s why […]

How to calculate hole spacing for joined linear guide rails

There are several reasons that a linear guide rail may be supplied in multiple sections rather than in one piece: the overall length is longer than the maximum offered by the manufacturer, the machine design or other space constraints don’t allow installation of a single piece in the length needed, or the risk of damage […]

How to calculate hole spacing for linear guide rails

Profiled linear guides—whether profiled rails, cam roller guides, shaft support rails, or plain bearing guides—are typically manufactured with evenly spaced mounting holes that allow them to be secured to a machine base or work surface. For rigidity and integrity of the rail, there’s often a minimum distance, specified by the manufacturer, that must be maintained […]

How to calculate combined static load

Static load capacity is an important factor in linear bearing selection. While dynamic load capacity is used to calculate bearing life, static load capacity indicates how much load the bearing can withstand before permanent damage occurs to the balls and/or the raceways. Even when they’re not moving, linear guides often experience a combination of both […]

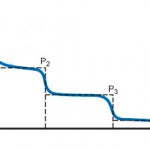

How to calculate mean equivalent dynamic load

It’s rare in linear motion for a guide or ball screw to carry the same load throughout its move cycle. Even in simple pick-and-place applications, the load will be higher in one direction (the pick and carry phase) than in the other direction (the place and return phase). But even more common is for a […]

Seven Interchange Tools for Linear Guides and Bearings

In linear motion, there are few types of components that are truly interchangeable—that is, where a product from one manufacturer is a dimensional and technical replacement with a product from another manufacturer. In fact, only linear ball bearings (bushings) and shafts are commonly interchangeable between manufacturers, with very few dimensional and technical differences. Not only […]

The top 10 Linear Motion Tips articles of 2015

With the range of technologies, designs, and options available for linear motion components, ploughing through the alternatives and making the best decision takes more time and resources than many designers and engineers are able to expend on any individual component. Looking back at the top 10 most-read Linear Motion Tips articles of 2015 confirms this situation. From primers on […]

How do self-aligning linear bushings work?

Linear bushings, also known as ball bushings, are linear bearings that ride on a hardened, round shaft to provide linear guidance with low friction. The first linear bushing designs were patented in 1945 and became commercially available in the 1950’s. Until the introduction of profiled rail linear guides in the 1970’s, linear bushings served as the […]

Ball rail systems: twice the service life and high travel accuracy

The patented entry zone of the new BSHP ball runner blocks from Rexroth improves travel accuracy and work piece quality while greatly increasing load capacities and service life. These runner blocks are available in most sizes, versions, and accuracy classes. BSHP ball runner blocks are 100% interchangeable into existing profiled rail applications using the same […]