The need to replace a linear guide in an existing machine or assembly can arise for any number of reasons: to improve the stiffness of the assembly by changing to a bearing with higher preload, or to accommodate unforeseen space constraints by using a different bearing type or style. And sometimes, a linear guide needs to be replaced […]

Ball + roller guides

What are recirculating linear bearings?

Linear ball and roller bearings can be broadly divided into two categories—recirculating and non-recirculating—depending on whether or not the rolling elements actually flow (or circulate) through the bearing housing. In order to understand what a recirculating linear bearing is, let’s first take a look at bearings that don’t recirculate. Non-recirculating linear bearings Non-recirculating bearings have […]

Custom dovetail slides (and other linear components) from Gilman Precision

Gilman Precision sells myriad custom products with an array of size, accuracy range, and complexity variations. Gilman can tailor specific dimensions to given motion applications. For more data and information regarding customization options and assemblies, email sales@gilmanprecision.com. Dovetail slides for simple and cost-effective precision movement Base width is 1.00 to 36.00 in. and base length is to 200.00 in. long. Hardened-way slides for ruggedness […]

What is L10 life and why does it matter?

One of the fundamental steps in selecting a recirculating linear bearing, whether profiled rail or round shaft type, is to calculate the bearing life. But how is this calculation derived, and what does it mean in the “real world?” Bearing life for recirculating linear bearings, often referred to as the L10 life, is a method […]

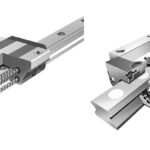

New Profile Rail Linear Recirculating Bearings from Lintech

Lintech’s MR, ARC, and HRC Profile Rail Linear Recirculating Bearings incorporate two or four rows of recirculating balls arranged in a 45 degree contact angle with the raceway. The rigidity under moment and torsional loads is increased by this design. Larger ball size is used to enhance the load capabilities. This design offers equal loading in all […]

When is static load capacity important?

When sizing a recirculating bearing, most designers and engineers focus on bearing life, which is based on dynamic load capacity. This is the load at which a linear recirculating bearing will, with 90 percent certainty, achieve the targeted service life before fatigue occurs. Static load capacity, on the other hand, is the force that causes permanent […]

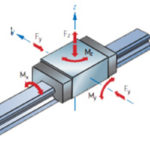

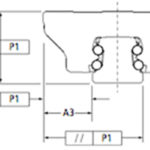

How to choose linear guide accuracy

When choosing a recirculating linear guide, there are several criteria that need to be specified, including size, preload and accuracy. And although the term “accuracy” is often used in a generic sense, when referring to recirculating ball or roller guides, it designates five characteristics: Height tolerance of the rail and block assembly Permissible difference in height between […]

FoodStream Pillow and Flange Blocks: FDA/USDA and 3A-Dairy Compliant

FoodStream electroless nickel plated pillow and flange blocks from LM76 are FDA/USDA/3A-Dairy compliant linear motion components. They complement LM76’s line of FDA compliant bearings, scraper seals, and shafting. FoodStream off-the-shelf pillow and flange blocks are ideal for use in processing and packaging food, producing pharmaceuticals, the BioPharma industry, and in medical devices. Inch size FoodStream […]

How to choose linear guide preload

When choosing a recirculating linear guide, one of the key criteria in the specification is preload. Linear guide preload eliminates the clearance between the bearing block and the rail, which increases rigidity and reduces deflection when external loads are applied. To achieve preload, manufacturers use balls (or rollers, in the case of roller bearings) whose diameter is […]

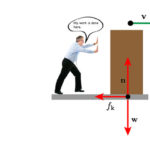

What is stick-slip?

Stick-slip, also referred to as “stiction,” is the bane of engineers and machine builders who need smooth, precise motion. Simply put, it’s the jerkiness that can plague both plain and recirculating linear bearings when they transition from standstill to motion. Here’s why stick-slip happens… When two objects slide against each other, friction works against their motion. […]