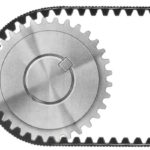

Synchronous belts transmit power via positive engagement between belt teeth and pulley grooves, making them suitable for applications that require high torque and making them less prone than traditional V-belts to slip in dynamic applications. But even synchronous belts can experience failure if they’re not installed, maintained, and applied properly. One way that toothed belts can fail — and fail catastrophically — is via tooth shear. Below are some of the most common causes of tooth shear in synchronous belts, and how to avoid them.

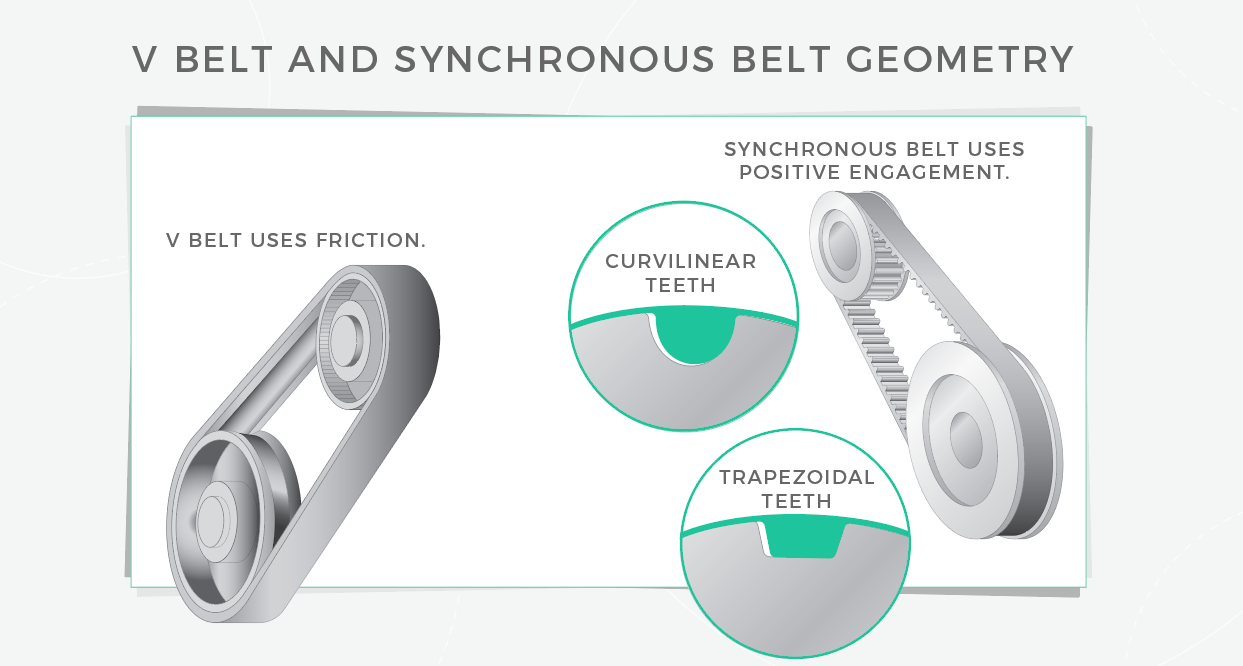

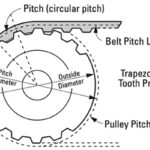

The shear strength of a synchronous belt tooth is determined by the cross-section of the tooth, the contact area between the tooth and the pulley, and stress concentrations within the belt. Trapezoidal tooth profiles are widely used in motion applications, but curvilinear tooth profiles often have higher shear strength than trapezoidal shapes due to the curvilinear design’s lower stress concentrations.

Application and use

The most widely-recognized cause of tooth shear is high torque or shock loads. When these excessive loads occur, the teeth engaged with the pulley can develop cracks at the root of the tooth, which then extend to the tip of the tooth and lead to the tooth shearing from the belt.

The most effective ways to avoid this cause of tooth shear are to limit the amount of torque delivered to the belt by the motor and to eliminate the possibility of shock loads occurring. However, these solutions aren’t always practical or achievable, so belt sizing should taking into account the possibility of excessive torque and shock loads.

Installation and maintenance

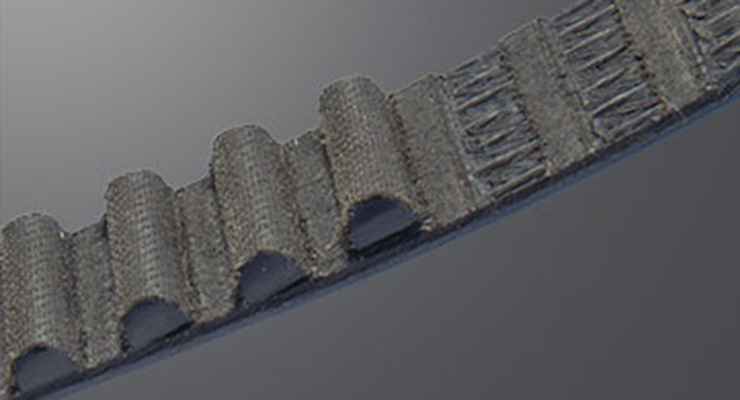

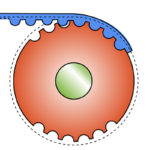

Angular misalignment of the belt pulleys can also lead to tooth shear. Misalignment of the pulleys causes the belt to experience uneven tension across its width, and the side of the belt experiencing the higher tension can develop cracks at the roots of the teeth. If these cracks travel across the width of the belt, tooth shear can result. Pulley misalignment is relatively easy to measure and correct, as demonstrated in this whitepaper from Gates Corporation.

Image credit: Pfeifer Industries, LLC.

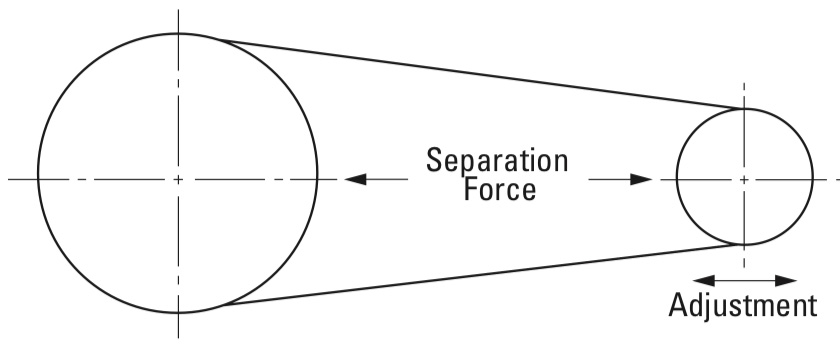

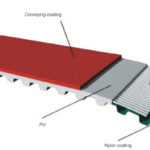

Another cause of tooth shear is belt tension that is too high or too low. Belt tension that is too high can cause shear simply due to the force on the engaged teeth. On the other hand, belt tension that is too low can cause the belt teeth to ride out of the pulley — a condition referred to as “self-tensioning.” When this happens, the load is carried farther down the tooth flank, rather than at the root of the tooth. This causes the tooth to bend and rotate, which can result in the tooth tearing at its base and separating from the belt.

Image credit: Gates Mectrol

Real-world testing is often advised to determine application-specific tension requirements, but manufacturers offer guidelines or suggested “starting values” for belt tension based on whether the application is for motion transfer, power transmission, or registration (positioning).

Leave a Reply

You must be logged in to post a comment.