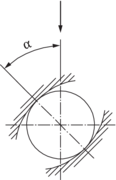

In profiled rail linear guides that use balls or rollers, the geometry and arrangement of the bearing raceways play a significant role in the bearing’s load capacity, friction, rigidity, and ability to withstand errors in mounting. But there’s another aspect of a bearing’s design that also plays a role in its load capacity and rigidity — the contact angle.

The ISO 14278 standard for linear motion rolling bearings defines the nominal contact angle as:

The angle between the direction of load on the linear bearing and the nominal line of action of the resultant of the forces transmitted by a bearing raceway member to a rolling element

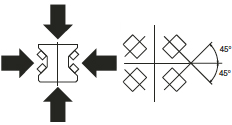

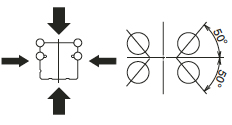

45 degree contact angles for equal load capacity

Linear guides that use Gothic arch geometry — including miniature profiled rails and most roller bearing guides — have four-points of contact between the ball and the raceway, which results in a contact angle of 45 degrees.

Image credit: NSK

The benefit of the 45 degree angle is that it provides the bearing with equal load capacity in all four primary directions — radial (downward and lift-off) and lateral (side) loading. This means the guide can be used in any orientation without the need to de-rate the load capacity.

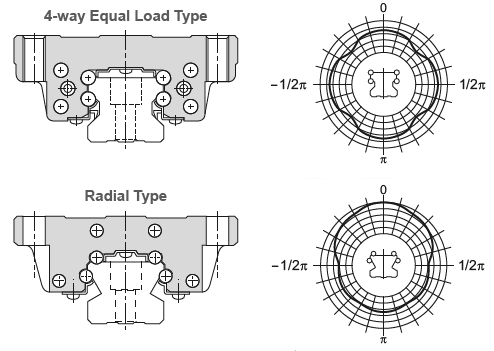

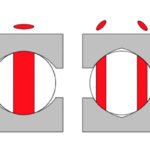

Bottom: When the contact angle is larger for the top rows of balls, the load capacity is higher in the radial direction but lower in the reverse radial and lateral directions.

Image credit: THK

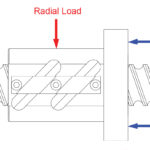

Higher contact angles for better radial load capacity

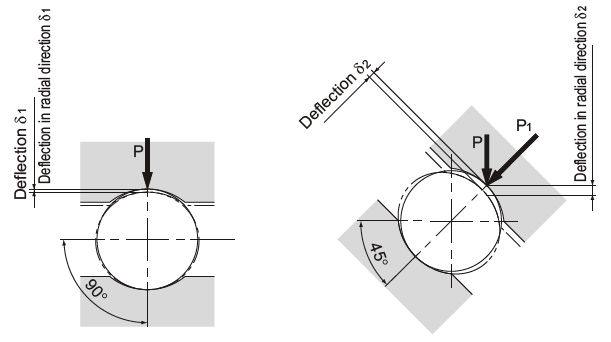

Linear guides that use circular arc or offset Gothic arch geometry, on the other hand, can be designed with varying contact angles to produce higher load ratings in one direction, although at the sacrifice of load capacities in the other direction.

For example, one circular arc design uses a contact angle of 90 degrees on the top rows of balls, with a smaller angle of 30 degrees on the lower rows of balls. This gives the bearing extremely high load capacity for radial (downward) loads — which is the primary loading direction in many applications — since the load is being transferred from the top rows of balls directly downward into their raceways. It also gives the bearing very high rigidity (low deflection) when radial loads are applied. The tradeoff for higher load capacity and rigidity in the radial direction is lower load capacity and rigidity in the reverse radial and lateral directions.

Image credit: THK

Another design, based on the offset Gothic arch geometry, uses a 50 degree contact angle for all four rows of balls. This provides higher load capacities in both the radial and reverse radial directions, but lower load capacity in the lateral direction.

Image credit: NSK

Leave a Reply

You must be logged in to post a comment.