Replacing precision ground ball screws on legacy equipment is complicated by the dissolving of original manufacturers and by product customizations. Offering multiple types of ball screw return designs provides the flexibility needed to keep older equipment running.

The long life of machine tool equipment has resulted in machine tools which are often older than their operators and may be on their second or third corporate owner. When the ball screws on these machines need repair or replacement, owners are often challenged to find support because the original manufacturers are no longer in business or the model is no longer supported. This can be complicated by operational or guarding modifications which have been applied over decades. Further still, many legacy ball screw assemblies use external ball return tubes, which are susceptible to damage, premature wear, speed limitations, noise, and abnormal package size. When a machine begins to experience ball screw backlash, the lack of an adequate replacement precision ball screw assembly can make useless an otherwise operable machine.

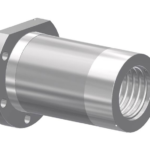

Every ball screw application has critical parameters, including screw diameter, housing/ball return diameter, nut length, thread pitch, dynamic load capacity, maximum load capacity, and speed. Balancing these needs for replacement applications can rarely be accomplished with a catalog design or single ball return system, since their performance and form factor often vary greatly.

Having both button return and end cap return technologies closes the gap in selecting appropriate replacements for legacy applications. These two technologies, combined with customization and engineering support, help balance the disparate functional needs of most machine tool applications. For some applications, button return offers the smallest nut diameter. For other applications, end cap return offers multiple thread start options, which doubles load capacity and increase life. Both solutions help replace external tube returns and their functional/repair limitations.

Dynatect LSI has recently developed end cap return solutions with additional advantages. One benefit is reduced wear with fingerless pickup, which eliminates the common end cap wear point and allows for refurbishing. Another benefit is blind lead on screw, which results in fewer threads needed for loading nut on ball screw and up to 25% cost savings.

Dynatect’s LSI precision ground ball screw division has over 30 years of machine tool experience, maintains an ISO 9001 manufacturing facility, and offers custom ball screws and returns for thousands of applications. Dynatect offers some of the broadest precision ball screw repair options, and with the end cap return, also offers a wide range of replacement options. In 2018, Dynatect is already offering repair, replacement, and new ball screws at a small fraction of the industry lead time. There are now more options than ever before for restoring machine tools back to their original operation. Machine owners with custom, legacy, and abandoned machines can find the widest selection of repair and replacement precision ground ball screws and return options at Dynatect.com/ball-screws.

Leave a Reply

You must be logged in to post a comment.