Vadnais Heights, Minn. – Nexen’s new enhanced Roller Pinion System (RPS) provides high-accuracy linear positioning with zero backlash and simple installation in precision motion control applications.

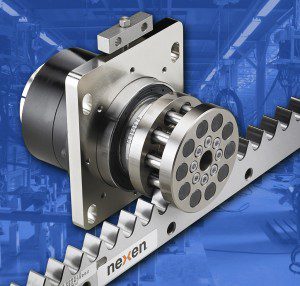

The RPS features an ISO 9409 flange mount pinion and pinion preloader, making it easier for system integration. The system has high precision surfaces and an adjuster that allows the pinion to be easily moved up or down in the rack, while maintaining proper pinion orientation to the rack.

The pinion consists of bearing-supported rollers that engage a unique tooth profile. Two or more rollers connect with the rack teeth in opposition at all times, eliminating backlash. The RPS rollers approach the tooth face in a tangent path and then smoothly roll down the tooth face, greatly reducing noise levels associated with other linear motion systems, such as tooth slap or ball return noise. The low-friction design delivers more than 99% efficiency in converting rotary to linear motion, greatly reducing wear and providing longer service life at high speeds up to 11 m/sec (36.1 ft/sec). The RPS rack is available in standard segmented lengths of one meter and half meter increments and can be custom cut as required, allowing unlimited run lengths and easily accommodating diverse application requirements.

With a new line of integration solutions for ISO 9409 flanged gearheads, the innovative RPS system is now even easier to install in a broad range of linear motion applications. Flange mount pinions can be directly mounted to the gearhead, ensuring the highest degree of stiffness and accuracy, with no shaft or bushing required. Since the direct mount pinions rigidly secure close to the drive bearings, they ensure high performance. Additionally, the pre-loader system includes everything needed to properly integrate the RPS, regardless of the orientation.

For more information, contact Nexen Group, Inc., at 651-484-5900 or via email at info@nexengroup.com

Leave a Reply

You must be logged in to post a comment.