The thread design of a power transmission screw—whether a lead screw or a ball screw—plays a critical role in the screw’s function. Aside from the basic thread form (acme, trapezoidal, etc.), the three main aspects of the thread geometry—helix angle, lead angle, and thread angle—help to distinguish different types of screws from each other and play a role in determining their performance characteristics.

Lead angle

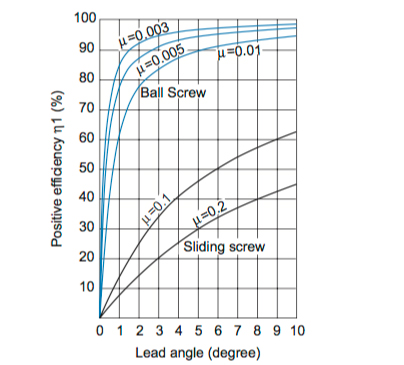

The efficiency of a screw is mainly influenced by three factors: friction, lead, and lead angle. For lead screws, the high friction produced by sliding contact between the screw and the nut means that friction is the most significant contributor to efficiency. Conversely, since ball screws use rolling elements with very little friction, their efficiency is primarily dependent on lead angle.

The helical nature of a screw thread can be compared to an inclined plane wrapped around a cylinder, like a rotary wedge.

Lead angle is the angle between the helix of the thread and a line perpendicular to the axis of rotation.

Image credit: tools-n-gizmos.com

Recalling from trigonometry class, the tangent of an angle equals the side opposite the angle divided by the side adjacent to the angle. So the tangent of the lead angle, B, equals the lead of the screw divided by the circumference of the screw.

![]()

![]()

β = lead angle

L = screw lead (mm)

dm = root diameter of screw (mm)

Below is a sample chart showing the relationship between lead angle and screw efficiency, for both ball screws and lead (sliding) screws. As you can see, ball screw efficiency begins to reach its maximum at a lead angle of 10 degrees.

Image credit: THK

For ball screws, the lead angle also influences the preload torque of the screw assembly, which is used in drive torque calculations.

![]()

Tp = torque due to preload (Nm)

Fp = preload (N)

L = screw lead (mm)

Helix angle

The terms “lead angle” and “helix angle” are often used interchangeably, but the helix angle is the angle between the helix of the thread and a line parallel to (rather than perpendicular to) the axis of rotation. Looking again at the depiction of lead and helix angles, you can see that they are complementary; their sum must equal 90 degrees.

Since the helix angle is the angle opposite the lead angle, its equation is given as:

![]()

![]()

Helix angle is generally used to describe gear teeth, whereas lead angle is used when referring to screw geometry.

Thread angle

Another geometric specification of screws is thread angle, or simply, the angle between threads.

Thread angle is a common characterization of lead screws, with acme screws having a thread angle of 29 degrees and trapezoidal screws having a 30 degree thread angle. Ball screws, on the other hand, use a radial raceway that conforms to the rolling ball elements, so they are typically characterized by their raceway geometry—Gothic arch or circular arc.

Leave a Reply

You must be logged in to post a comment.