Linear ball and roller bearings can be broadly divided into two categories—recirculating and non-recirculating—depending on whether or not the rolling elements actually flow (or circulate) through the bearing housing. In order to understand what a recirculating linear bearing is, let’s first take a look at bearings that don’t recirculate.

Non-recirculating linear bearings

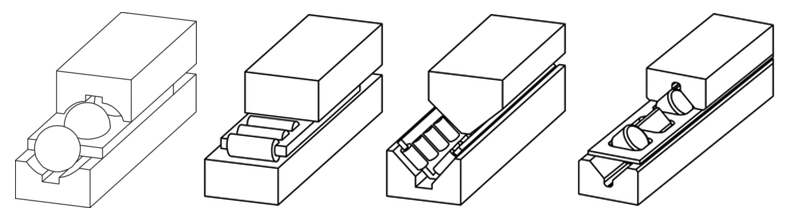

Non-recirculating bearings have balls or rollers that are contained in a housing and directly support a load. As the bearing moves, the rolling elements rotate about their own axes, but they do not travel within the housing. Although their basic construction principle is the same, there are several types of non-recirculating bearings, based on the type and arrangement of their rolling elements, as shown below.

Image credit: ISO

Regardless of their different rolling mechanisms and designs, all non-recirculating bearings have a few things in common. First, the length of the bearing and the number of rolling elements limits the stroke that can be achieved. Second, because their rolling elements only rotate (no recirculation), they provide extremely smooth motion. And with machined top and bottom surfaces, they can have extremely high travel accuracy. Non-recirculating bearings are often the guide system of choice for high-precision stages and are commonly used in machine tool, precision scanning, and measuring applications.

Recirculating linear bearings

“Circulate” means “to move in a circle or circuit; to move or pass through a circuit back to the starting point.” And the term “recirculate” means to do this over and over again. Hence, recirculating bearings have rolling elements that move continuously through a circuit, or path, within the bearing. This design allows the bearing to travel any distance, regardless of the bearing length. In other words, where non-recirculating bearings have limited travel, in theory, recirculating bearings have unlimited travel, constrained only by the length of the rail or shaft guideway.

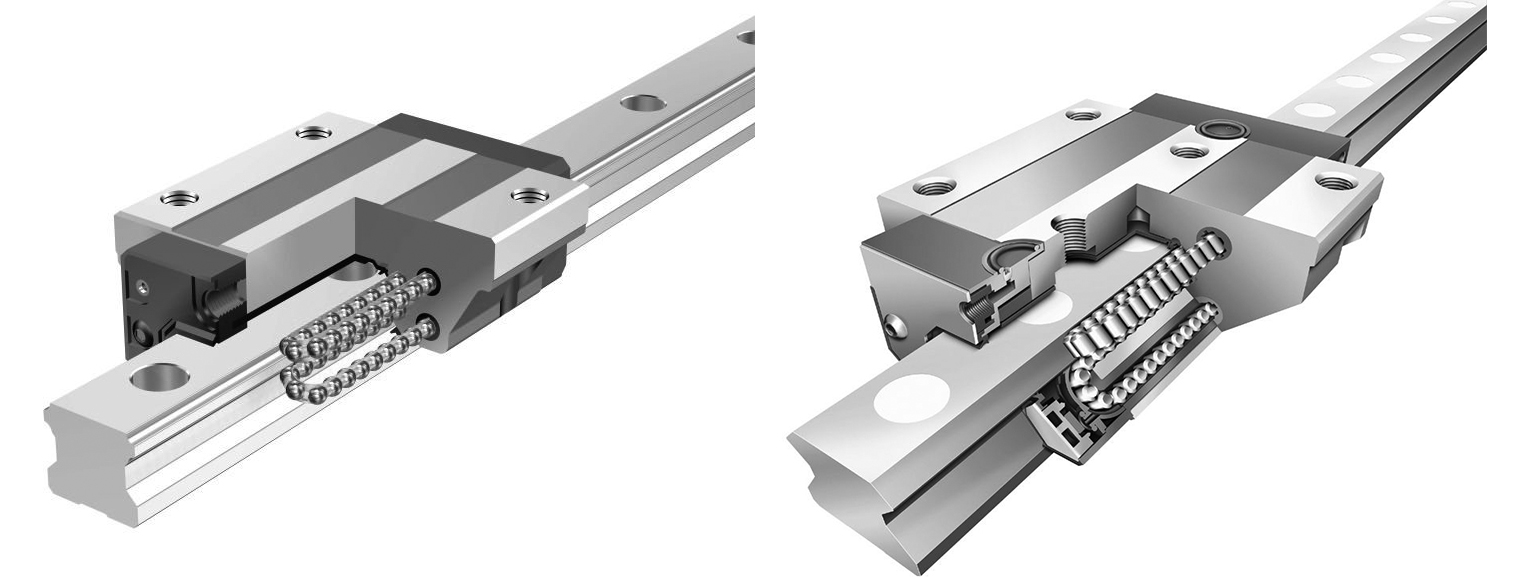

Recirculating linear bearings include round shaft designs and profiled rail designs. Round shaft bearings use balls as the load-carrying elements, but profiled rail types can use either balls or cylindrical rollers.

Image credit: Schaeffler Group Inc.

Recirculation does present some challenges though. First, as the balls or rollers circulate through the bearing, they move from a non load-carrying zone (sometimes referred to as the return zone) to a load-carrying zone. This variation of the balls (or rollers) from a non-loaded to a loaded state causes pulsations, which affect the bearing’s travel accuracy. Improving the smoothness of the circulation process has been a priority for manufacturers in recent years, with new designs for the recirculation zone yielding improved travel accuracies.

Recirculation also limits the maximum speed that the bearing can achieve, due to the forces created on the bearing end caps when the recirculating elements make the “turn” around the circuit. One way to reduce these forces is to reduce the mass of the balls. Some manufacturers have done just that by offering profiled rail bearings with ceramic balls. These versions can achieve speeds up to 10 m/s, but with a somewhat reduced load capacity.

Although recirculating bearings generally have lower travel accuracies than non-recirculating types, they come in a wide range of sizes, preloads, and accuracy classes, making it easy to find a recirculating linear bearing that fits just about any application requirement.

It is really helps to understand how the bearings affects on your machine performance. Thanks for sharing this amazing information about recirculating linear bearings process.