Medical devices used for diagnosing and treating cancer are taking advantage of advancements in measurement and motion control.

Medical technology, as well as precision measurement / motion control advances, have come a long way in recent years. With continued R&D in both, new and exciting combined developments have emerged. That’s the case with the advent of a new dedicated solution for breast cancer radiotherapy. Patients treated on the GammaPod will likely only need between one to five treatments in order to eradicate certain breast cancers, which is much shorter than the current six-week, five days a week course of radiation.

This revolutionary new system by Xcision Medical Systems, LLC of Maryland is called the GammaPod, and is currently in clinical trials at the University of Maryland School of Medicine in Baltimore. At the core of this new machine is a moving bed for a prone patient and a patented two-cup system that holds and stabilizes the breast with the target. This allows a targeted and powerful dose of radiation using 36 Cobalt-60 sources that can be administered in new and unique ways, with less dose to normal tissue.

“The emergence of accelerated partial breast irradiation (APBI) as a breast cancer treatment option is an example of personalized medicine replacing a one-size-fits-all approach,” explains Xcision’s VP of Engineering Peter Maton. “This has the potential to change the way early detected breast cancer is treated, to the point of sometimes eliminating surgery altogether, and at a lower cost than traditional procedures.”

Design for accuracy and redundancy

The moving bed and cup system are unique to the GammaPod. The movement is designed using precise motor controls, gear boxes, and linear bearings, as well as five linear encoders on the bed and two rotary encoders on the bowl system. The encoders provided by HEIDENHAIN provide absolute position values from the moment they are switched on. Even movements that occur while the system is without power are translated into accurate values once the system is powered up again.

“Using HEIDENHAIN’s absolute encoder system has allowed us to minimize the uncertainty of the zeroing process otherwise required for incremental encoders and the time-consuming nature of it,” explains Maton.

The absolute encoders are used for a secondary positional measurement to verify correct positioning which ensures the accuracy of the delivered dose. The direct mounting and absolute calibration provide real-time quality assurance of the bed positioning system.

One of the key design goals of the GammaPod system is to create a practical, and comfortable means of prone treatment and Xcision executives believe they’ve accomplished that. A patient will approach the GammaPod bed while it’s in a vertical position, step on and position the breast cup to be locked to the bed, which will then gently glide into the horizontal position.

With a patient lying face down on the machine bed, rather than on their back, the breast to be treated naturally falls further away from the chest wall, helping to minimize dose to organs in that region.

The five absolute LIC 4100 linear encoders are incorporated within the GammaPod table, which serve to monitor the table’s position, and thus verify the patient’s position. These linear encoders are directly mounted on the two table support columns. On each column, Xcision separately monitors the height and lateral offset of the table and the fifth monitors the length axis.

The linear encoders are rigidly mounted to the table. “This gives us an absolute stable positioning readout because they are directly mounted to the things we are controlling. With that, we have accurate confirmation of XYZ position in order to be sure the cup is in the correct location for the radiation,” adds Maton.

The LIC 4100 exposed encoders are characterized by permitting absolute position measurement both over large traverse paths (up to 28 m), at high accuracy and at high traversing speed, although Xcision only needs around 400 mm of travel.

The absolute nature of the linear encoders is critical because it allows for detection of primary system failure or calibration error. According to Maton, with the redundant secondary system, the position of the patient is confirmed to be free of such failure or calibration errors, thus ensuring treatment of the correct location in the breast.

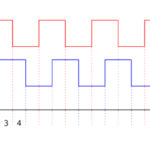

“We control the radiation on/off and beam size by relative rotation of two bowls, one holding the sources and the other holding the blockers/collimators. We utilize two drive systems that must be controlled within a tight tolerance,” explains Maton. The two HEIDENHAIN EQN 1023 absolute rotary encoders on the drive systems provide independent confirmation of the alignment accuracy.

“The redundant check provided by the absolute rotary encoders ensures that we know the radiation sources are in the right position at all times, relative to the blockers / collimators,” explains Maton. “So in real time, the readings are being checked in both primary and secondary systems. We had started off with relative magnetic encoders in our design, but they were not satisfactory for a couple of reasons. First, we had the problem of having to rotate very slowly in order to find the zero point at each power up, and second, it turned out they weren’t linear enough for our needs. So the HEIDENHAIN absolute encoders were the better answer to drive our system.”

Treatment delivery

As mentioned, Xcision’s GammaPod uses a two-cup system to encapsulate the breast for treatment. The inner cup is designed to constrain the shape of the breast. Suction between the cups gently pulls the breast to completely fill the inner cup, and immobilize it. The patient is imaged on a CT scanner, then without removing the cup, moved to the treatment device and the cup is locked into the treatment bed. A copper wire (referred to as a fiducial marker) embedded in the cup is used to establish a 3D coordinate system which is used for treatment planning to create the bed position sequence (control points) for the treatment.

The focused and concentrated dose of radiation is delivered according to this sequence. The focus means that the dose will fall off sharply outside the target volume, reducing dose to healthy breast tissue, organs such as the heart and lungs, and to the skin. This decrease in collateral dose minimizes unwanted exposure and side effects.

The planned treatment is based on the established coordinate system and motion control, and includes a specific amount of time for the radiation beams to remain in each position in order to achieve the correct distribution of dose. The system is designed to match a planned dose and delivered dose within one millimeter.

Rotary servo table drives optoacoustic imaging system

Scientists at Tomowave Laboratories use technologies based on light and sound to make imaging systems for the healthcare industry. These technologies use optoacoustic and laser ultrasonic methods to produce modalities such as a laser optoacoustic ultrasonic imaging system, which uses pulses of laser light with a dark red color. (Optoacoustic tomography (OAT) is a technique for generating high-resolution images of biological tissue that scatters light waves, typically biological tissue.)

Biological tissue absorbs this light, causing it to heat-up by a fraction of one degree. The resulting temperature increase causes an increase in pressure, which generates ultrasonic (optoacoustic) waves. The imaging scanner uses arrays of transducers to measure these ultrasound waves at different locations to generate images of internal tissue of different human and animal organs, such as breast or prostate. These systems listen to the sound of light, allowing doctors to detect and diagnose cancer and other conditions.

Recently, engineers at Tomowave developed a system that combines light and sound to generate three-dimensional images of tissue submerged in the imaging module, primarily the tissue of small animals used for research purposes and development of new contrast agents or therapeutic methods.

This optoacoustic tomography system is the first of its kind to produce functional 3D images of biological tissue with equally high resolution in each volumetric direction. The system provides comprehensive information on anatomy and function. These images are especially useful for studying the distribution of blood and its oxygenation level.

Imaging module

Preclinical research systems rotate the object of study, while the module itself rotates in systems used in clinical settings such as breast imaging systems. Noninvasive breast imaging systems apply the same technology to produce three-dimensional volumetric optoacoustic images and a stack of two-dimensional ultrasonic images, allowing for image co-registration.

These systems produce scans at different wavelengths in minutes with minimal patient discomfort. Custom software processes the volumetric data according to the specific items of interest, which may include hemoglobin content, oxygen saturation and vasculature visualization.

The imaging system uses a PSR180UT low-profile rotary servo table from IntelLiDrives to rotate the imaging module at a constant speed, which is programmed in advance. A real-time precision encoder output allows synchronization of the image capture with the motor’s position, allowing the system to reconstruct the images in three dimensions.

HEIDENHAIN – heidenhain.com

Xcision Medical Systems – xcision.com

Tomowave – tomowave.com

IntelLiDrives – intellidrives.com

Leave a Reply

You must be logged in to post a comment.