Implementing linear motion in a cleanroom presents a particularly difficult challenge, since motion – whether rolling or sliding – necessarily produces particles. But by understanding the sources that contribute to particle generation and implementing smart design options, it is possible to achieve linear motion without compromising even the most stringent cleanroom environments. Below are five ways to make your linear motion system more cleanroom friendly through simple design considerations and adaptations.

1. Lubrication

The primary purpose of lubrication is to reduce friction and, therefore, particle generation, between moving surfaces. But it also traps the particles that are generated, preventing them from being scattered into the environment.

However, lubrication itself can be a major contributor of contamination, in two ways. First, the components that make up lubricants have a tendency to outgas, where oil vapors and microscopic droplets are released into the air. To avoid this, use cleanroom-approved lubricants, which have lower outgassing properties and smaller concentrations of contaminating particles.

Second, rotating components can “sling” off grease and cause significant degradation of the cleanroom environment. Keeping this direct contamination away from critical work areas is extremely important. This is where the next consideration, seals and covers, becomes important.

2. Sealing

In a typical industrial application, seals and covers are used to protect the motion components from contamination. But in a cleanroom application, their main purpose is to keep the contamination generated by the system inside the system. To accomplish this, low-friction or non-contact seals are the best choices. Bearing seals that don’t make contact with the raceways will help to keep lubrication and friction-generated particles inside the linear system, without producing additional contamination.

For linear actuators, static covers (no bellows!) will add another barrier against particles being dispersed into the cleanroom environment.

3. Mounting

When designing a motion system, the orientation of the components (vertical, horizontal, upside-down) is typically chosen to minimize the forces and moments on the system. But in a cleanroom, mounting orientation impacts the release of particles into the atmosphere, which is a more critical factor than system dynamics.

The best mounting solution, if it can be achieved, is to keep the moving components below the work area. The laminar airflow of the cleanroom will evacuate particles from the environment without giving them the opportunity to contaminate critical work areas above. In addition, a right-side-up mounting orientation does a better job of trapping particles inside the system than a vertical or upside-down orientation.

4. Materials

While stainless steel and PVC are the preferred materials for cleanroom equipment, these aren’t always practical for linear motion systems that are tasked with providing good load-carrying capability and long life. For linear motion, aluminum and steel remain the materials of choice.

When aluminum is used, it should be anodized to prevent contamination caused by oxidation, and steel components should be treated with a plating or coating that is suitable for cleanroom environments, such as Nickel plating. And don’t overlook hardware, such as screws and fasteners, which are commonly black-oxide coated – a poor choice for cleanrooms due to its high rate of particle shedding. Instead, these should be replaced with stainless steel versions.

5. Vacuum

The final step to making a linear motion system cleanroom friendly is to ensure that contaminating particles never make it into the environment in the first place. The most effective way to achieve this is by implementing a vacuum purge on the actuator or system.

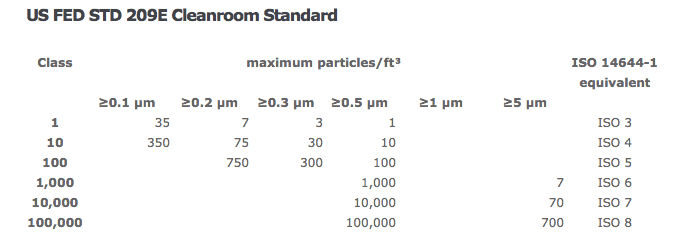

While vacuum purge is relatively common in cleanroom equipment, the key to making this work is to understand the sources of particle generation. The most obvious sources are the rolling and sliding surfaces, such as linear guides and ball screws. But less noticed, and just as culpable, are areas such as the motor coupling and the cable carrier joints. By analyzing all the moving components and implementing a vacuum purge system accordingly, the cleanroom compatibility of a linear motion system can be reduced by anywhere from one to three levels – for example, from Class 1000 without vacuum purge to Class 1 with vacuum purge.

Considering the multitude of sources – both moving and static – that contribute to particle generation, it’s no wonder that many designers cringe when they find out that a linear motion system will be operating in a cleanroom. But motion doesn’t have to be the enemy of the cleanroom. With an understanding of the particle sources and corresponding design adaptations, it is possible to achieve cleanroom-friendly linear motion.

Leave a Reply

You must be logged in to post a comment.