The well-known bearing life equation, often referred to as L10 life, is a fundamental element in the sizing and selection of recirculating linear bearings. Through statistical analysis and real-world testing, the L10 life equation can predict, with 90 percent reliability, the life that a recirculating bearing can be expected to achieve. But even this universally adopted formula has some caveats to its use. Case in point: here are four things to keep in mind when using the L10 life equation to choose a linear bearing.

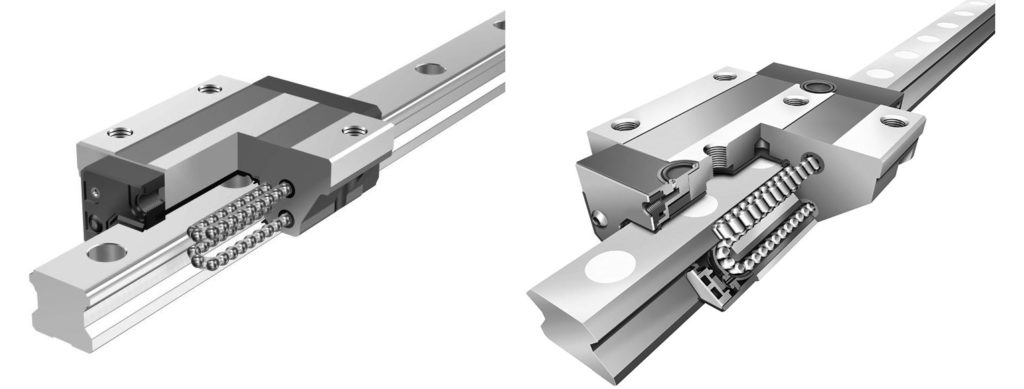

Balls or rollers? The choice matters.

First, remember that there are two variations of the L10 bearing life equation, so be sure to use the correct equation based on the recirculating bearing type.

Image credit: Schaeffler Group Inc.

For bearings with point contact (those that use recirculating balls), the bearing life equation is:

![]()

For bearings with line contact (those that use recirculating rollers), the bearing life equation is:

![]()

Service life: 50 km vs. 100 km

Also keep in mind that the L10 life of a linear bearing can be based on a service life of either 50,000 meters or 100,000 meters.

![]()

Or

![]()

Why does this matter? Because if a bearing’s expected service life is only 50,000 meters (rather than 100,000 meters), it will be able to withstand a greater load. In other words, the dynamic load capacity of a bearing rated for 50,000 meters of service life will be greater than the load capacity of a bearing rated for 100,000 meters of service life.

To make an “apples-to-apples” comparison between bearings with different service life ratings, the dynamic load capacity of the 50,000 meter bearing should be divided by a factor of 1.26.

![]() Or, the dynamic load capacity of the 100,000 meter bearing should be multiplied by a factor of 1.26.

Or, the dynamic load capacity of the 100,000 meter bearing should be multiplied by a factor of 1.26.

![]()

(For the derivation of the 1.26 correction factor, check out this article.)

It’s important to note that some manufacturers use different service life ratings for various product lines, so be sure to verify which service life was used to determine the dynamic load capacity, even when comparing different bearings from the same manufacturer.

When the load varies throughout the move…

The L10 life equation is based on the applied dynamic load, but few applications involve consistent loads that don’t change over time. It can be tempting to simply use the highest load applied to the bearing for the purposes of calculating life, but this can lead to costly oversizing, increased weight and inertia, and higher friction.

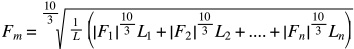

For non-constant loads, the more accurate value to use in the life equation is the mean equivalent dynamic load, which takes into account each discreet loading phase and the percentage of total travel for which each load is applied.

For ball bearings, mean equivalent dynamic load is calculated with the formula:

![]()

And for roller bearings, the mean equivalent dynamic load formula is:

Static loads also affect bearing life

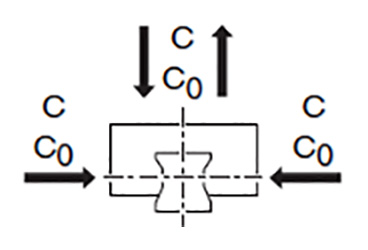

Image credit: Bosch Rexroth Corp.

The L10 bearing life is based on the amount of load the bearing can carry while moving (the dynamic load) before fatigue failure occurs. But it’s common for linear bearing to experience static loads as well as dynamic loads.

Static loads can be caused by pressing forces that occur when the bearing is stationary or by shock loads and vibrations. It’s important to compare these loads, together with any static load safety factor recommended by the manufacturer, to the bearing’s static load capacity.

Static loads in excess of the bearing’s rated static load capacity can cause permanent deformation of the bearing surfaces, which degrades the smoothness of operation and reduces bearing life.

Leave a Reply

You must be logged in to post a comment.