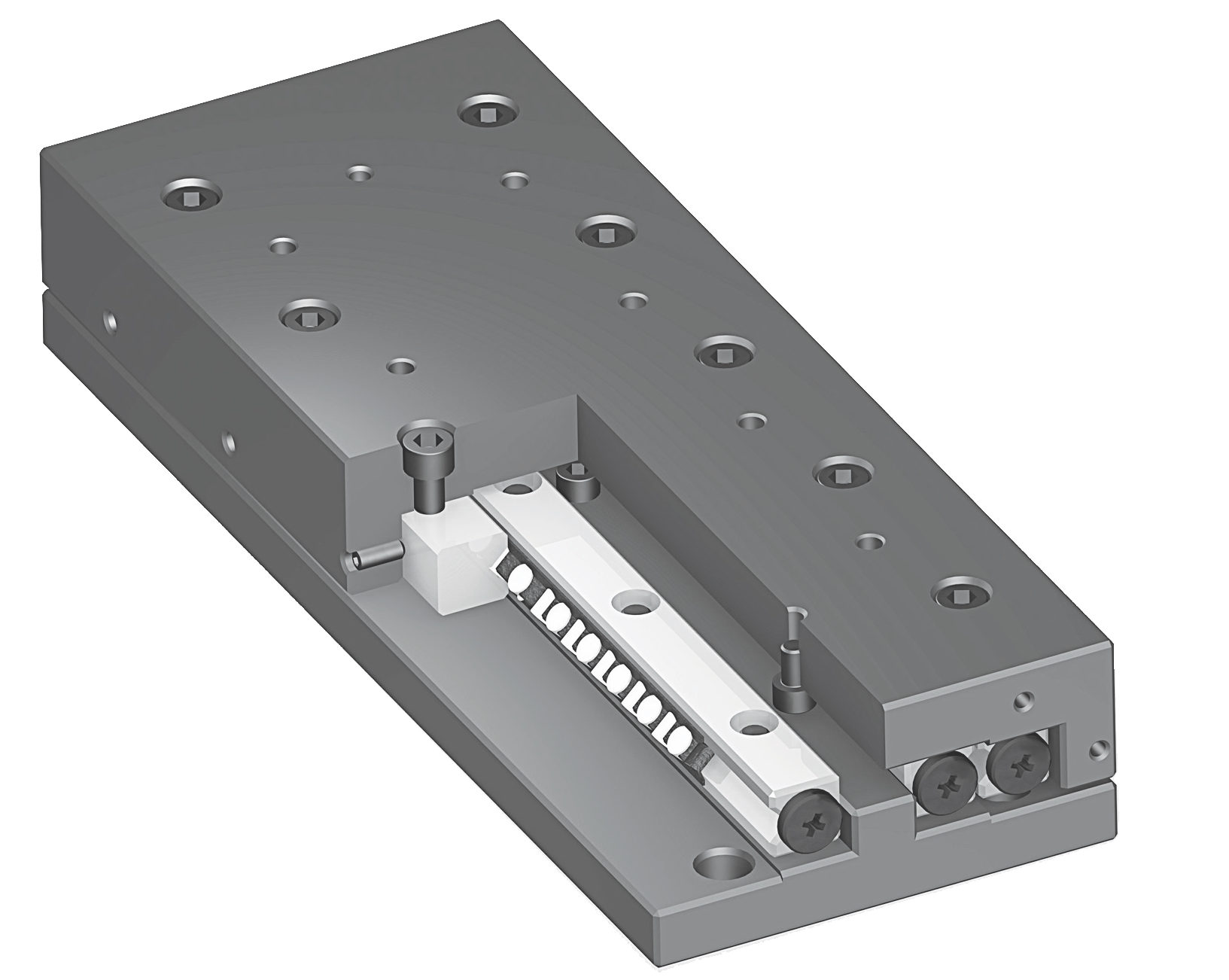

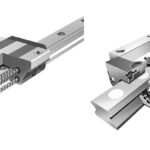

← PREVIOUS PAGE || Note that because rollers in the vast majority of crossed-roller bearings don’t recirculate, table length and overall roller count limit maximum possible stroke length. Even so, where stroke lengths don’t exceed a meter, crossed-roller slides often outperform recirculating linear bearings. Rollers (rather than balls) as the load-carrying elements makes for greater load capacity with line contact with the raceways (and not point contact). This also boosts the rigidity and accuracy of the linear axes into which they integrate.

At the risk of complicating the topic, there do exist crossed-roller slides (or at least contained carriages that mate to essentially standard guideways) with recirculating roller circuits. Though far less common than the traditional (non-recirculating) crossed-roller types, these recirculating-roller slides excel in applications that must bear high loads and require rigidity (delivered by crossed-roller arrangements). Another technology that competes against traditional crossed-roller slides here is air bearings. The latter carry heavy loads even while maintaining exceptionally smooth motion, but lack the stiffness of mechanical bearings. Air bearings are also costly both upfront and during operation.

Crossed-roller slides are often designed and assembled by component manufacturers with preload to eliminate clearance …

Leave a Reply

You must be logged in to post a comment.