Gears, and in particular, gearboxes, are common in linear motion applications, providing speed reduction and torque multiplication for systems driven by belt and pulley or chain and sprocket assemblies. The diversity of gear types and materials available for industrial applications makes it important (albeit somewhat challenging) for designers and users of linear motion systems to understand the primary strengths and uses of each.

Our sister site, motioncontroltips.com, has covered a wide range of gearing and gearbox topics to help you do just that.

Power transmission gears – technical summary – A complete overview of the main gear types, including planetary gears and gearboxes.

What is a gearbox? – More specific information on what constitutes a gearbox and where gearboxes are most commonly used.

Spur gears – Spur gears are the simplest type of gear and are used in a wide range of applications.

Helical gears – Another common gear type, helical gears provide smoother motion, less noise, and higher speed capabilities than spur gears.

Hypoid gears – With shafts that are non-intersecting and non-parallel, the unique design of hypoid gears makes them suitable for high-speed applications.

Worm gears – Worm gears provide large reduction ratios and high torque multiplication.

Self-locking worm gears – Like fine-pitch lead screws, worm gears can also be self-locking, meaning they cannot back drive.

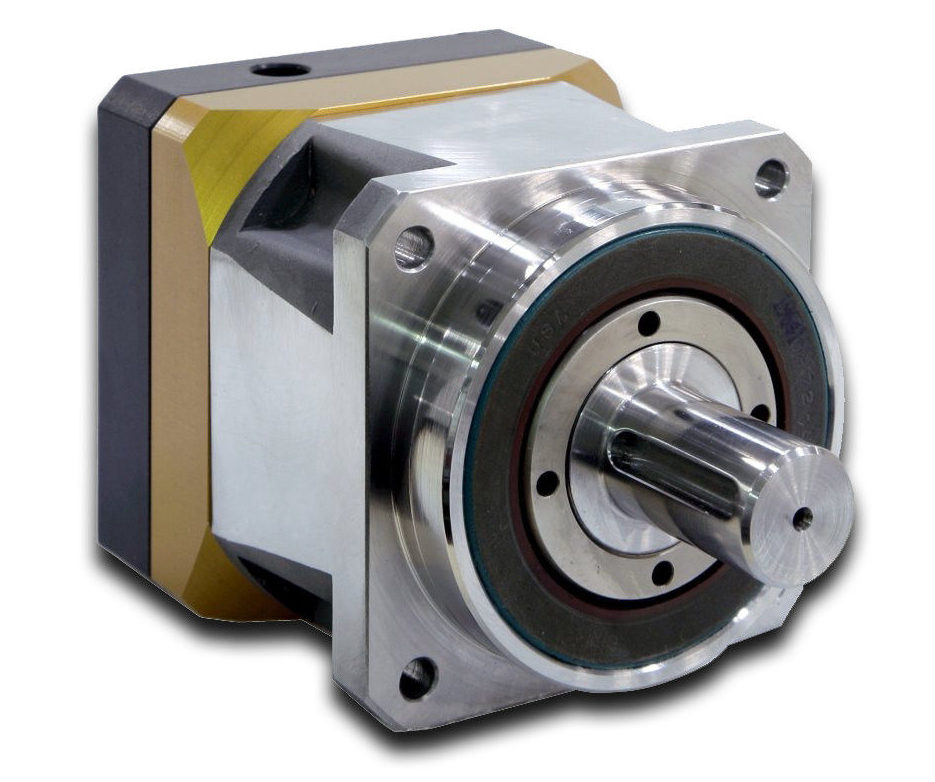

Planetary gearboxes – The most common choice for servo applications, planetary gearboxes have higher stiffness than most other gearbox designs.

Plastic gears – When the environment is unsuitable for metal gears, plastic gears are often a feasible solution.

Gearbox lubrication – Both the method and quantity of lubrication are important factors in gearbox maintenance.

Worm gear lubrication – With bronze gears and sliding contact between components, worm gears require lubricants that meet special criteria beyond those required for other gear types.

Pitch line velocity – The linear velocity between teeth is an important factor in the selection of a gearbox lubricant.

Industrial gears: New materials and manufacturing – A discussion of advances that are taking place now – and some that are soon to come – in the industrial gear market.

How The Jetsons undermined the understanding of the gear industry – Who would have thought that a cartoon from the 1960s would shape (or misshape) our understanding of gears?

Feature image credit: Neugart GmbH

It’s good to know that spur gears are the simplest type of gear. That probably means they’ll be easier to replace if they break or go missing. I’m trying to build something that needs a lot of gears so I’ll probably just use that kind.