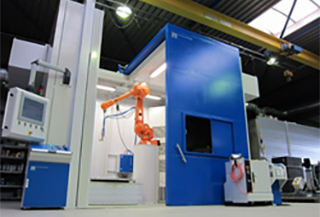

Helix Linear has announced the acquisition of a Robotic Coating System (RCS) for applying its proprietary H4X PTFE coating to lead screws. This is the most advanced coating system in the industry and allows Helix to precisely apply the highest quality PTFE coatings to their precision lead screws. The PTFE coating acts as a dry lubricant and eliminates the need for wet lubricants such as oil or grease. Using the Helix PTFE coating can increase the life of a lead screw assembly by two to four times.

The new RCS allows Helix to maintain a constant thickness of the coating along the entire length of the screw, which guarantees a consistent amount of torque and efficiency. Coating thicknesses of 0.04 to 0.08 inches are applied to the lead screws in a controlled environment to ensure the strongest adhesion possible.

The new RCS allows Helix to maintain a constant thickness of the coating along the entire length of the screw, which guarantees a consistent amount of torque and efficiency. Coating thicknesses of 0.04 to 0.08 inches are applied to the lead screws in a controlled environment to ensure the strongest adhesion possible.

Engineers designing medical devices, laboratory automation equipment and semiconductor equipment used in clean environments are often restricted from using grease or oil as a lubricant, so the Helix H4X PTFE applied by the RCS is a perfect solution for delivering smooth, clean and quiet lead screw assemblies.

Precision coating with PTFE makes a stunning improvement to the performance of a lead screw assembly. Coupling Helix’s internally lubricated acetyl nut material with the PTFE coating on their lead screws delivers a truly innovative linear motion solution.

Leave a Reply

You must be logged in to post a comment.