The six-axis parallel-kinematics systems known as hexapods excel in motion simulation and testing of mechanical and drive systems, multi-dimensional position sensors, and (the focus of this article) image-stabilization designs for cameras and video equipment.

By Doris Knauer • Project Manager — Industrial Automation | Physik Instrumente (PI)

By Doris Knauer • Project Manager — Industrial Automation | Physik Instrumente (PI)

Modern camera systems are capable of astounding feats, including:

• Capturing sharp pictures in fast-changing ambient conditions

• Taking snapshots of moving scenes sans blurring

• In automotive driver assistance systems, recognizing traffic signs and road marks

• In surveillance systems, identifying dangerous situations

To help quantify the quality of still and video images and fairly compare competitive imaging devices from different suppliers, some testing equipment uses hexapods to simulate the movements to which cameras are subject during operation. That’s of keen interest to end users such as smartphone and camera manufacturers and those in the automobile and aerospace industries (as well as the security and automation technology sectors) wanting to maximize the quality of the stills and video images their products generate.

Of top interest are comprehensive tests that measure devices’ output-image resolution, contrast, color, texture, zoom, and exposure — as well as their autofocus and image-stabilization capabilities. A typical test collects and analyzes thousands of images for statistically significant results of all attributes.

The challenge is that image-quality test results are only comparable when cameras and camera components are tested under consistent conditions and methods.

Consider DXOMARK, a French camera and video-device laboratory and testing company for manufacturers of DSLR and DSC products, smartphones, video-based driver assistance systems, and devices for surveillance, aerospace, defense, and machine-vision applications. DXOMARK offers serves for the analysis, comparison, and optimization of image quality. The company’s Analyzer system consists of hardware, software, and extensive testing protocols bundled within several modules for repeatable operator-independent results. Different modules can be used and combined depending on the task at hand or on the image quality attributes under evaluation. A unique Analyzer capability (a visual noise measurement) quantifies visual noise metrics directly correlated with visual perception. Video analysis encompasses exposure, white balance, definition, and texture for changing lighting conditions; automated lighting scenarios can also be programmed for user-specific test requirements. The latest version of Analyzer even includes a Selfie module to enable accurate and repeatable testing of smartphone front cameras.

The measurement methods for the DXOMARK evaluation have been developed in collaboration with several companies that contribute to international standardization working groups such as IEEE/CPIQ and ISO TC42-WG18.

The image stabilization test assesses how well a camera’s built-in optical and electronic image stabilization systems work. These systems work to compensate for device movements to prevent blurring of captured images. For example, sensors measure linear and angular motion accelerations, such as a photographer’s shaky hands or the vibrations of vehicles and aircrafts, so that the system can automatically offset these influences and avoid blurred images. The effectiveness of image stabilization systems (whether optical or electronic) is assessed using a Camera and Imaging Product Association (CIPA) protocol established by Japanese camera manufacturers for defining motion-simulation test conditions.

Motion simulation with high repeatability: All image-stabilization test methods demand reproducible camera shaking of a camera and vehicles and aircrafts vibrating.

“We must ensure that the simulated frequencies and movements such as those around the rotation axes (θX, θY, θZ — pitch, yaw, roll) are identical for each test,” says Nicolas Touchard of DXOMARK. “We currently use hexapods in the latest version of Analyzer, because hexapods deliver precisely reproducible motions up to 30 Hz for many potential test scenarios.”

Camera and smartphone tests typically require up to 12 Hz … but the image stabilization functions of driver-assistance systems require much higher frequencies. Thanks to their parallel-kinematic design, hexapods excel in such precise motion and vibration simulation applications. They outperform serial (stacked) systems in such testing with better path accuracy, repeatability, and flatness.

In addition, the moved mass is lower for better dynamic performance … which is the same for all motion axes. Moreover, cable management is no longer an issue, because no cables move on the platform. Plus the system has a much more compact design.

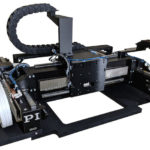

Suitable specifications and qualified support: The hexapods used in the latest version of Analyzer are from the German precision positioning-technology company Physik Instrumente (PI).

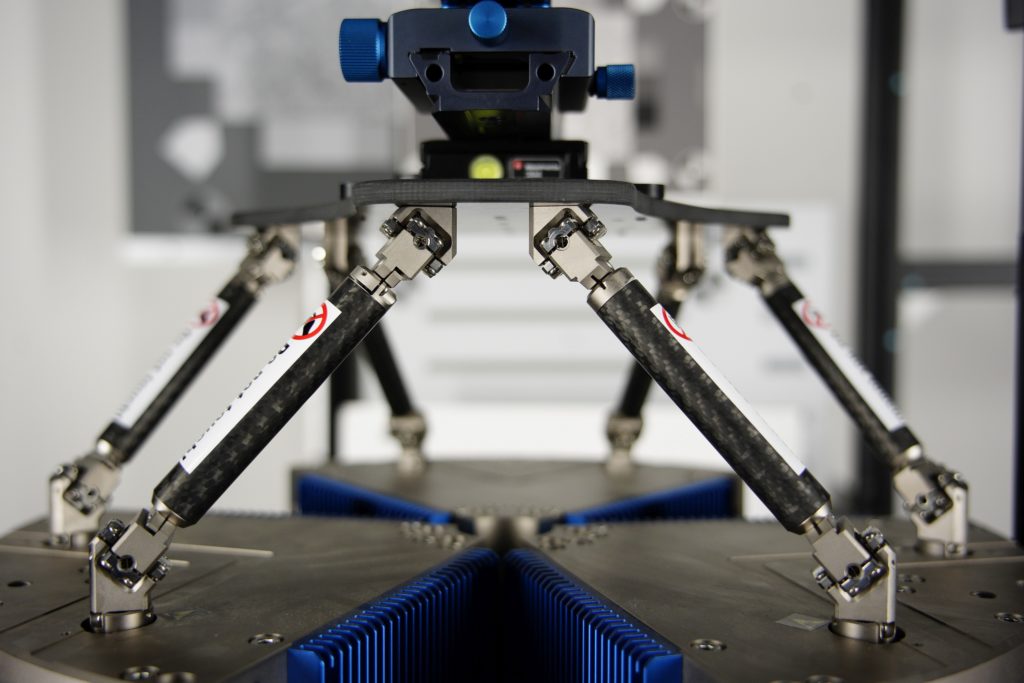

Case in point: The PI H840 hexapod (certified to CIPA Standard DC-011-2015) allows testing of image-stabilization systems. The CIPA standard defines rotational axes, test frequencies, and vibration amplitudes.

Since mid-2019, another hexapod is being used in the Analyzer. The H860 hexapod is designed specifically for testing image stabilization systems. It offers simulation frequencies up to 30 Hz, and travels predefined trajectories, sinusoids or freely definable paths with a high degree of trajectory control. Due to its friction-free voice coil drives and lightweight design — consisting of extremely stiff carbon fiber parts with low moving masses — it can achieve fast and smooth motion, as well as high acceleration.

The hexapod is fixed to a base plate with brackets to keep the test device safely in place during vibration simulation. “We chose these hexapods for vibration simulation and because PI provides qualified support — for example, in the form of software-driver adaptations,” adds Touchard.

Easy control and a freely definable pivot point: The high performance C-887 digital controller handles control over the hexapods and (with user-friendly software) enables easy configuration. Positions are specified in Cartesian coordinates, and the controller calculates the transformations to command the six individual drives. The hexapod’s freely definable rotation or pivot point is an essential feature that lets the hexapod platform adapt to the position of the camera’s image stabilization component — so the image sensor can be located in the middle of all six degrees of freedom, for example.

Another application of hexapods in in the calibration of gyroscopic compasses (according to DIN ISO 22090-1) for shipping and marine technologies. For more information, visit corp.dxomark.com and www.pi.ws.

Leave a Reply

You must be logged in to post a comment.