I once overheard a colleague, relatively new to linear motion and eager to be helpful, tell a customer, “H stands for our high-class rail.”

While the thought of a “high-class” rail was amusing, technically she was correct. In profiled linear guide terminology, H is the designation for high class …

… high accuracy class, that is.

When specifying profiled linear guides, there are three primary characteristics: size, which indicates the width of the rail; preload, which corresponds to the rigidity of the carriage under load; and accuracy.

In the world of linear motion, “accuracy” can mean different things, depending on the type of component being discussed. For profiled linear guide assemblies, the accuracy class is a standard specification, covering five characteristics:

– Height tolerance of the rail-carriage assembly

– Permissible difference in height of multiple carriages on the same rail

– Width tolerance of the rail-carriage assembly

– Permissible difference in width of multiple carriages on the same rail

– Parallelism between the reference surfaces of the rail and the carriage

To understand the difference between these accuracy specifications, let’s look at each one in a bit more detail.

Accuracy class and linear rail height

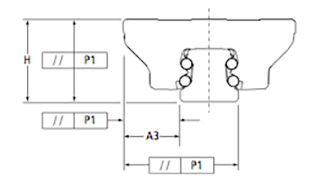

The height tolerance specifies the maximum deviation in height between the ground base of the rail and the ground top surface of the carriage, and is measured in the center of the carriage. In addition to the height tolerance of a single carriage on a guide rail, the maximum height difference between multiple carriages on the same rail is also specified. To determine the height difference between carriages, each carriage is measured at the same location on the rail.

Accuracy class and linear rail width

The width tolerance specifies the maximum deviation in width of the rail-carriage assembly, measured from the reference edge of the rail to the reference edge of the carriage. Like height, there is also a maximum allowable difference in width between multiple carriages on the same rail, measured with each carriage at the same location on the rail.

Accuracy class and linear rail parallelism

For profiled rail assemblies, parallelism is specified in two planes: the parallelism between the bottom ground surface of the rail and the ground top surface of the carriage (in the vertical direction, analogous to height), and the parallelism between the reference edge of the rail and the reference edge of the carriage (in the horizontal direction, analogous to width). Where height and width tolerances are measured in the static state, parallelism is measured in the dynamic state, while the carriage is moving along the rail. The parallelism of the assembly, therefore, is dependent on rail length.

Some manufacturers provide reference edges on both sides of the profiled rail, while some only grind one side of the rail as a reference edge. When the rail has only one reference edge, parallelism in the horizontal direction is measured with both the carriage and rail reference edges on the same side of the assembly. When either side of the rail can be used as a reference edge, the parallelism value will also apply when the rail and carriage reference edges are on opposite sides of the assembly.

When should you use a “high-class” rail?

Manufacturers offer at least three, and in some cases six or more, accuracy classes for profiled linear guides, with the most common being Standard, High, and Precision. But what influence does accuracy class have on performance, and when is it advisable to invest in a higher accuracy class?

Because most applications involve overhung masses, it’s rare that an assembly consisting of a single rail and carriage will be suitable for the resulting moment loads and forces. The most common arrangements are two carriages on one rail, two rails with one carriage each, and two rails with two carriages each. In these configurations, using a higher accuracy class can help avoid unnecessary stresses and preload forces due to geometric differences between the components, which can decrease life. In addition, higher accuracy classes provide a more uniform travel, improving machine accuracy, especially for long travel lengths.

Other factors influence the final accuracy of a profiled linear guide assembly, including surface preparation and mounting. But if you’re not using “high-class” rails and carriages, you may end up with low-class results.

Leave a Reply

You must be logged in to post a comment.