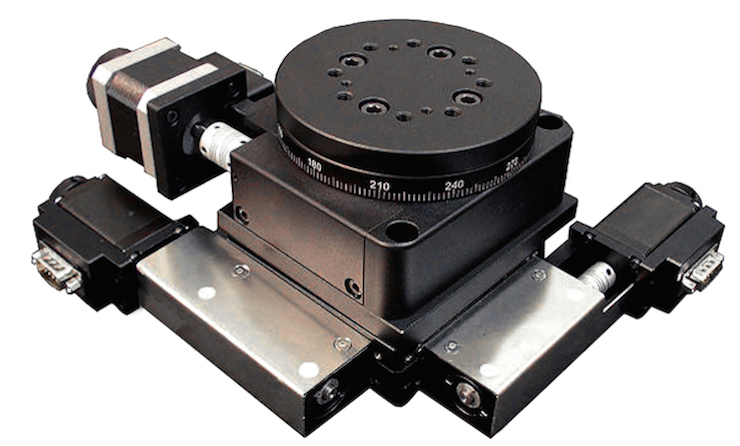

Two new economical XYR (Theta) alignment stages from Optimal Engineering Systems, Inc. (OES) offer high precision and repeatability for industrial, medical, semiconductor, research, and laboratory applications. The XYR-01-01 and XYR-01-02 Alignment Stages feature ± 7.5 mm of travel in the X and Y axes and ± 180° of rotation (theta).

The XYR-01-01 and XYR-01-02 Alignment Stages feature linear resolutions of the X and Y axes of 0.25 µm (micro-steps per step motor driver in use); the repeatability of each is 1.5 µm, positional accuracy is 5 µm, and backlash is 2 µm. The 1 mm per-turn ground lead screws and preloaded V-groove and crossed roller bearings add to the high precision and stiffness of these alignment stages.

The 60-mm diameter theta stage of the XYR-01-01 is driven by a 90:1 precision worm gear and the 100-mm diameter theta stage of the XYR-01-02 is driven by a precision 180:1 worm gear. The resolutions of each of the theta stages is 0.001° (micro-steps per step motor driver in use). Repeatability is 0.005°, positional accuracy is 0.001° and backlash is 0.005°.

Two-phase stepper motors are standard and a knob for manual adjustments of each axis can be replaced with an incremental encoder for position verification, or with a servo motor and encoder for closed-loop operation. These black anodized aluminum XY-Theta stages are easy to integrate into new or existing systems. Compatible motion controllers are available from OES and the XYR-01 -01 and 02 Alignment Stages can also be ordered as a complete plug-and-play system.

For more information, visit www.oesincorp.com.

Leave a Reply

You must be logged in to post a comment.