When a ferromagnetic material — such as iron, nickel, or cobalt — is subjected to an external magnetic field, the magnetic domains within the material align, creating internal stresses that cause the material’s shape or dimensions to change. This phenomenon is referred to as magnetostriction. Conversely, when a magenetostrictive material is subjected to a stress, its magnetic properties will change. This is known as the Villari effect.

Another manifestation of magnetostriction is the Wiedemann effect: When a wire is subjected to a magnetic field oriented parallel to its length, and a current is passed through the wire, the wire experiences torsional strain at the location where the magnetic field occurs.

The Wiedemann and Villari effects form the basis of linear magnetostrictive sensors.

All ferromagnetic materials experience magnetostriction, but in some materials, the magnitude of the dimensional change is too small to be of practical use. For example, when a magnetostrictive bar or rod is placed in a magnetic field oriented parallel to the length of the bar, the bar will change length. However, the length change for materials used in linear magnetostrictive sensors is very small — typically on the order of 10-6 m/m

In magnetostrictive sensors, the wire, or bar, is referred to as a waveguide. It is typically made from an iron alloy and is mounted to a stationary part of the machine. The magnetic field is provided by a magnet, referred to as a position magnet, which is attached to the moving part being measured. Short pulses of current (1-3 μs) are applied to a conductor attached to the waveguide.

Image credit: MTS Systems Corporation

As the Wiedemann effect states, torsional strain (twist) is induced in the waveguide, due to the interaction of the magnetic field caused by the current and the magnetic field caused by the position magnet. Because the current is applied as a pulse (referred to as an interrogation pulse), the twist travels down the wire as an ultrasonic wave, moving at approximately 2850 m/s. This twist, or mechanical pulse, is detected by a signal converter (also referred to as a strain pulse converter), which relies on the Villari effect to create a voltage pulse indicating receipt of the mechanical strain wave.

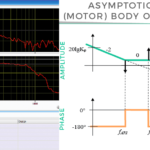

Image credit: Balluff GmbH

The time between the initial current pulse and the detection of the mechanical pulse indicates the location of the position magnet, and therefore, the position of the moving part being measured. The interrogation rate, or update rate, can range from one time per second to over 4000 times per second, with the maximum update rate determined by the length of the waveguide.

Magnetostrictive sensors provide absolute position information and, unlike incremental encoders, do not need to be re-homed when there is a loss of power. They can also use multiple position magnets with one waveguide, making them well-suited for applications that require position information for multiple components along the same axis, such as the knives on a slitting machine.

In addition to being non-contact, magnetostrictive designs enclose the waveguide in an extruded aluminum housing or stainless steel tube, so they are virtually impervious to contamination. They can also operate when there is a barrier between the position magnet and the waveguide — as long as the barrier is non-magnetic, such as ceramic, plastic, aluminum, or stainless steel.

Feature image credit: Balluff GmbH

Leave a Reply

You must be logged in to post a comment.