Round shaft guides are typically used with plain (composite, plastic, or bronze) or recirculating ball style linear bearings. But another type of round shaft bearing — referred to as a roller block or roller pillow block — offers better stiffness than plain bearings and higher speed capabilities than recirculating ball types.

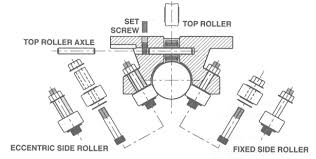

Instead of balls, a roller pillow block uses three cam rollers to support and guide the load: one on the top (this is the primary load-bearing roller) and one on each side. One of the side rollers is an eccentric cam that can be adjusted to provide the desired amount of preload or clearance.

Image credit: LM76

Two other styles — commonly referred to as double and twin pillow blocks — use six rollers: two on the top and two on each side. Double pillow blocks house all six rollers within the same dimensions as the standard, single pillow block, whereas twin pillow blocks are essentially two roller blocks machined into the same housing.

Image credit: PBC Linear

Roller pillow blocks are generally stiffer than plain bearings, and they can reach higher speeds than recirculating ball bushings. And the housings of roller pillow blocks are designed with the same mounting holes and distance from shaft centerline to mounting surface as traditional ball bushing pillow blocks, making them easy to interchange.

Image credit: PBC Linear

Image credit: LM76

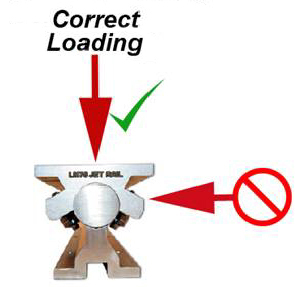

Load ratings for roller pillow blocks are typically much higher than for recirculating ball bushings of similar size. But with the top roller being the primary load-bearing element, roller pillow blocks can only support loads in one direction. Inverted mounting (with the mounting surface facing downward) is not possible, and vertical mounting or overhung loads are not generally permitted.

By using slots (instead of thru holes) for mounting, “floating” versions can compensate for misalignment of up to 0.125 in. between shafts. And the larger diameter of rollers — rather than balls — make roller pillow blocks more capable of withstanding the transition between sections of joined shafts, which are often required for travel lengths over 20 ft. Another unique feature of roller pillow blocks is their ability to traverse curved shafts.

The cam rollers used in roller pillow blocks can tolerate solid debris, such as dirt and chips, by “pushing” it out of the way as they travel along the shaft or by simply rolling over it. And like profiled rail bearings, side seals and scrapers can be added to help prevent contamination from entering the block. Although the rollers are lubricated and sealed, manufacturers often provide an optional lubrication port for the top roller, to help prevent accelerated wear when contamination, high speeds, or high temperatures are present.

The standard materials for roller pillow blocks include an aluminum housing (pillow block) and black oxide coated rollers. Liquid contamination and corrosives can be addressed with stainless steel or chrome plated rollers.

Roller pillow blocks are well-suited for applications such as woodworking, machining, and transport that require long lengths with joined shafts, high load capacity, and the ability to withstand contamination.

Feature image credit: Lee Linear

Leave a Reply

You must be logged in to post a comment.