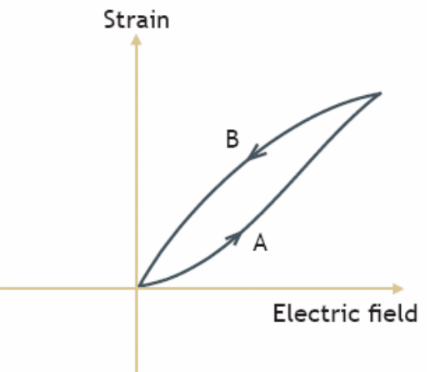

Piezo actuators operate on the principle that application of an electric field (voltage) induces strain (displacement) in the material — a phenomenon known as the inverse piezoelectric effect. But if you plot the strain versus the electric field of a piezo material, you’ll see that the strain doesn’t follow the same path when the field is removed and the strain is relieved as it did when the field was applied and strain was induced. This is because piezoelectric materials are also ferroelectric, and ferroelectric materials produce hysteresis loops when an electric field is applied and reversed.

The amount of hysteresis is defined as the ratio of the maximum difference between the two curves (A and B, below) to the maximum strain (displacement).

Image credit: Noliac

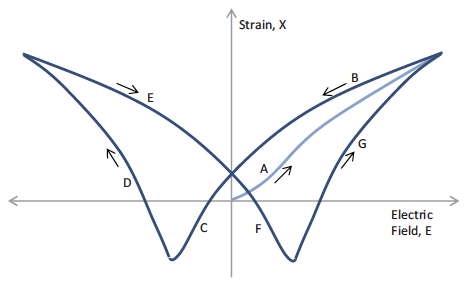

In fact, as a piezo material is cycled with positive and negative voltage — known as bipolar operation — the resulting displacement curve forms a butterfly shape.

Image credit: Aerotech

When the electric field (voltage) is initially applied, the increase in strain (displacement) in the piezo material is mostly linear, following the increase in electric field (A). The maximum strain is limited by saturation of the polarization within the material.

When the electric field is reduced, the strain at first decreases at a slower rate than that of the electric field (B). But as the electric field gets smaller, the strain begins to decrease at a faster rate than that of the electric field (C).

The piezo material reaches a point where its polarization has been fully reversed, and it abruptly changes polarity so that strain begins to increase again until it reaches its physical limit with negative voltage (D).

When the electric field reverses again and becomes positive, the strain again decreases more slowly that the field (E). But as the electric field gets smaller, the strain begins to decrease at a faster rate (F). Again, the piezo material reaches a point where it abruptly changes polarity and then the material expands again until it reaches its physical limit (G).

Hysteresis increases with applied voltage and can be as much as 10 to 15 percent of the commanded motion, although in some piezo actuator types, such as shear plates, it can be even higher due to the geometry of the actuator.

A similar effect seen in piezo actuator performance is referred to as creep. However, creep is displacement in the actuator that occurs when the applied electric field is unchanged.

When voltage is applied, a piezo actuator reaches its target displacement almost immediately, but the actuator continues to expand (or contract) after the voltage stops changing because it takes additional time for the individual dipoles within the material reorient and reach a steady-state. Creep can last for anywhere from minutes to hours, with the rate of creep decreasing over time.

Image credit: Noliac

Closed-loop operation of a piezo actuator can eliminate hysteresis and compensate for creep, improving the actuator’s positioning accuracy and repeatability.

Leave a Reply

You must be logged in to post a comment.