As an integral part of industrial machines and processes, ball screw assemblies often operate in environments with elevated temperatures. Heat can be generated by other mechanical and electrical components in the machine, and in some cases, is a byproduct of the process itself. And, like other motion products with sliding or rolling friction, ball screws generate heat of their own as they run. This heat, and especially the change in temperature that occurs over time, can have a detrimental influence on the screw’s function. But there are ways to mitigate heat and reduce its effect on life and accuracy.

Operating temperature recommendations for ball screw assemblies vary among manufacturers, but the typical upper limit for the most common ball screws is 80° C for short, instantaneous exposure, and 50° C for continuous duty. For standard annealed screws, a temperature over 100° C can cause a decrease in tensile strength and should be discussed with the manufacturer.

In addition to the environmental temperature that the ball screw is exposed to, the screw itself can generate heat, primarily due to frictional torque and rotational speed. Both factors—external temperature and internal heat generation—can cause thermal expansion in the screw shaft significant enough to affect its accuracy and performance. Every one degree of temperature rise will cause the ball screw shaft to expand by 12 microns per meter of length, which is demonstrated by the thermal expansion equation:

Δl = ρ * Δt * l

Where:

Δl = axial expansion (contraction) of the screw shaft (mm)

ρ = thermal expansion coefficient (12 x 10-6 / °C)

Δt = temperature change of the screw shaft (°C)

l = effective thread length (mm)

Effects of heat

The most significant consequence of thermal expansion is probably the effect it has on the ball screw’s lead. As the screw elongates, the lead changes, or expands, causing a loss of accuracy. To compensate for this, the lead is often set towards its minus side during manufacturing, and a travel compensation factor (determined experimentally and based on application type) is applied. Screw shaft expansion also increases the load on the ball screw support bearings, so this must be considered when sizing and designing the assembly.

Seals and other plastic materials, such as pick-up fingers and recirculation pieces, are also affected by heat. In high-temperature applications, the best option is to remove as many non-metal pieces as possible from the assembly. But this is rarely feasible since recirculation mechanisms are necessary for operation, and seals and wipers protect the ball nut from contamination and maintain lubrication inside the ball nut. To enable ball screw use in high-temperature applications, most manufacturers offer special plastic materials, such as Viton, that can withstand temperatures above 100° C.

Prevention and mitigation

There are several measures to prevent or compensate for high environmental temperatures and thermal expansion of a screw shaft. The most straightforward preventive measure is to choose the largest lead possible. The larger the lead, the farther the travel per revolution, so the slower the screw turns to travel a given distance in a given amount of time. The slower the rotational speed, the lower the heat generation.

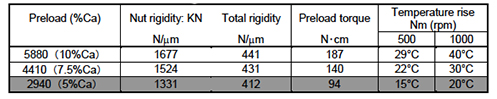

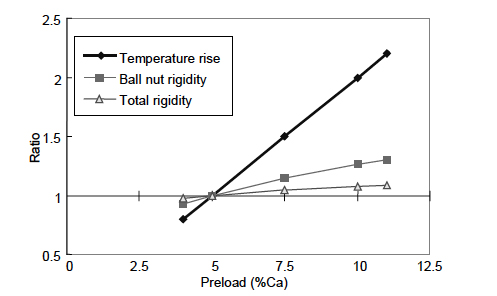

Another preventive measure includes choosing the appropriate preload for the application. Preload is often associated with rigidity, but its effect on rigidity is much less significant than its effect on heat generation. To help avoid excessive heat generation, designers should choose the lowest preload that’s acceptable for the application, and rely on the end bearing configuration to provide the necessary rigidity.

Image credit: NSK Ltd.

There is also a relationship between temperature rise and lubrication. Lubrication generates heat over time, and this effect is more pronounced when the lubricant has a higher base oil viscosity. Therefore, it’s best to choose a lubricant with lower viscosity when the application involves high temperatures. Another important factor is to apply the proper amount of lubrication, as this will help avoid heat generation due to rolling or sliding friction.

From a ball screw assembly design standpoint, there are several options to mitigate the effects of heat. First, the screw can be mounted in tension to help counteract any expansion due to temperature rise in the screw. Also, hollow screws can be used with internal cooling mechanisms to reduce the temperature of the screw. External, forced-air cooling can also be effective at mitigating heat and is generally easier to implement than internal cooling.

does the room temperature also has the effect on it?