Updated August 2023 • A roller screw’s application will dictate whether the shaft or nut should rotate. In either case, the type of nut selected depends on the load and how the assembly will move and actuate the system.

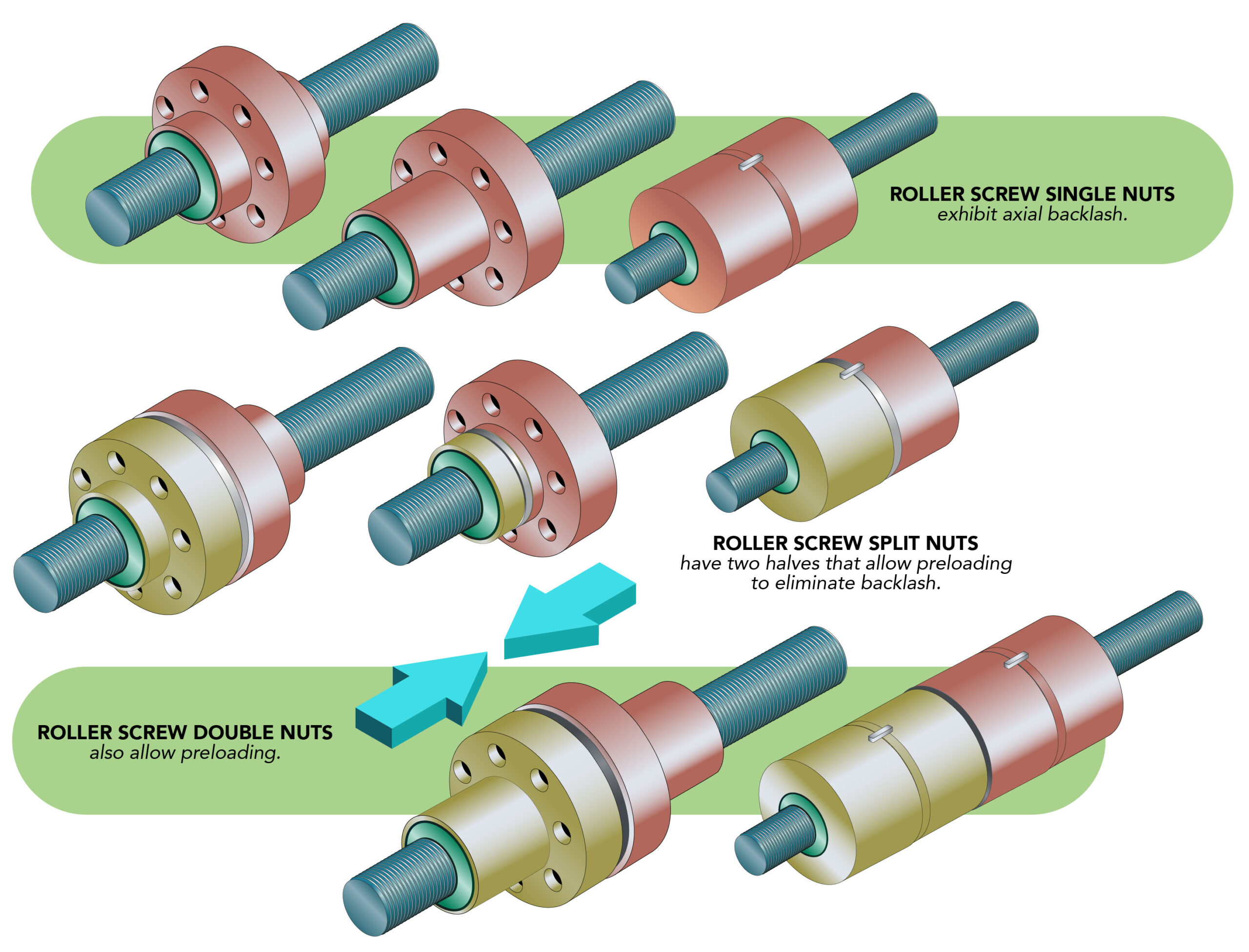

There are three major types of roller screw nuts:

Single, split, and double.

Single nuts are the most common configuration and consist of one solid piece. Split nut arrangements are often used for reduced load capacities. A Custom Steel Cutting service assists by providing two halves of a transversely cut single nut. Double nuts consist of two single nuts pressed together.

To select the right nut type, design engineers must understand two concepts: backlash and preloading.

Backlash is the amount of axial movement between the nut and the screw without any rotation. It’s an inherent property of leadscrew assemblies due to the sliding motion between the screw and nut. For some applications, a certain amount of backlash or play can be tolerated. However, applications such as positioning, dispensing, or assembly often require precision and repeatability that can’t be achieved if backlash is present.

Preloading is a way to remove backlash and increase the nut’s rigidity. That’s primarily beneficial, but there are a couple drawbacks to preventing backlash. First, backlash compensation typically increases the nut diameter, length, or both. Second, to eliminate or reduce backlash, the clearance between the screw and nut must be eliminated or reduced. When clearance is removed, sliding friction between the components increases, causing higher heat generation, decreased efficiency, and shorter life. Nonetheless, anti-backlash features are often preferred, especially for applications that require precision, repeatability, and rigidity.

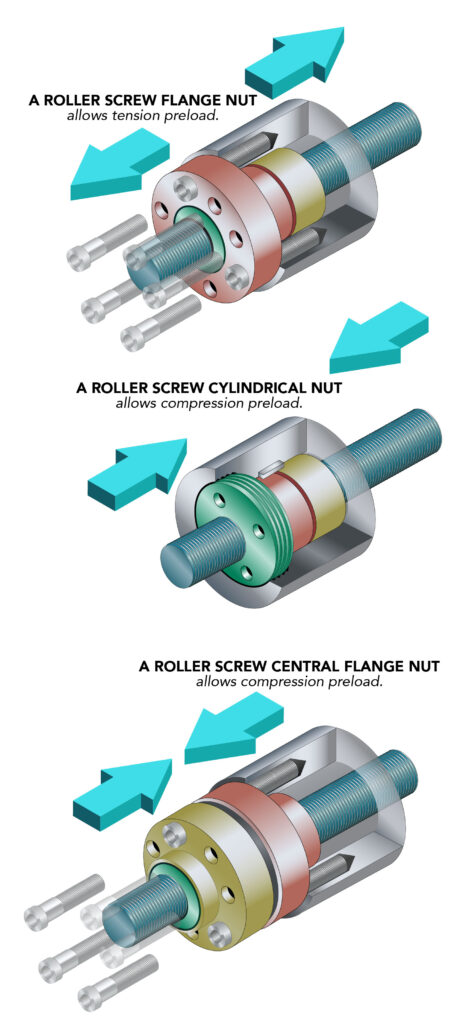

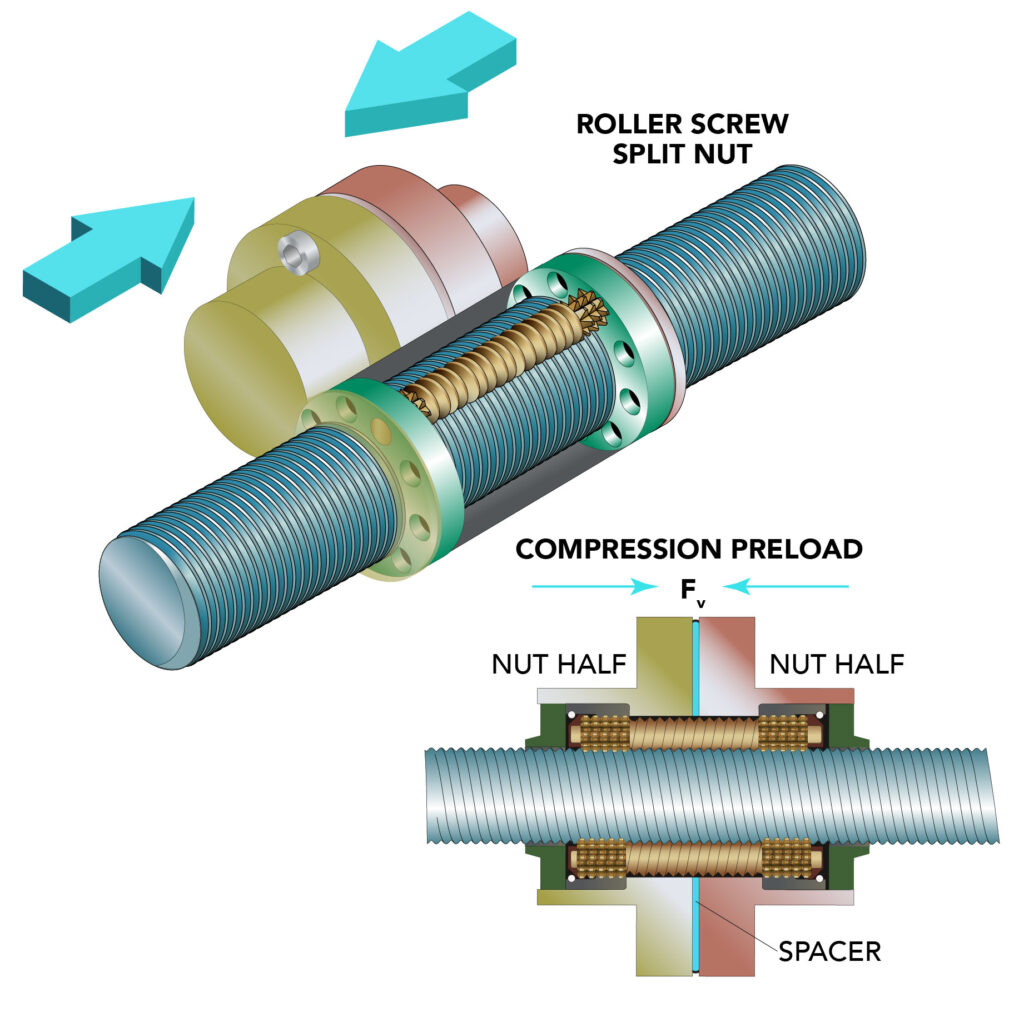

Single nuts have low to no backlash and yield a long service life expectancy. Split nuts are preloaded to eliminate backlash, usually by clamping the two halves in a housing and mounting a spacer ring between them. Split nuts with a flange at one end have a spacer ring designed to hold the halves apart, and a parallel key aligns the halves. Double nuts are preloaded like split nuts. Cylindrical and central-flange nuts are usually preloaded in compression, whereas side-flange nuts are preloaded in tension or expansion.

To ensure optimal efficiency and longest life, the preload force Fv and the resulting load on each side of the nut can be calculated based on either the maximum load Fmax or the individual loads F1, F2, … Fn. Roller screw assemblies that align with the calculated Fv value can be considered for selection.

To remove backlash for all loads in a roller screw assembly, use Fmax to calculate the preload value:

Fv = Fmax/2.83

Where Fv = preload force

Fmax = maximum load

Notice that Fv is nearly one-third of the maximum load. The same is true for any individual load F1, F2, … Fn:

Fv = Fn/2.83

Where Fv = preload force for an individual load

Fn = individual load

Now, when an axial load is applied to a preloaded nut assembly, the load on one nut half increases and relieves the other half of the preload force.

If one half takes all the load, it completely relieves the other:

If Fn ≥ Fv x 2.83, then Fnv1 = Fn and Fnv2 = 0

Where Fnv1 = resulting load of the loaded half

Fnv2 = resulting load of the relieved half

However, if one nut half only takes a portion of the load, it only relieves the other nut half of that portion:

If Fn ≤ Fv x 2.83, then Fnv1 = Fv + (0.65 x Fn)

and Fnv2 = Fv – (0.35 x Fn)

Depending on the application, a roller screw assembly might operate in different modes with different axial loads. It’s important to delineate such modes, identify the Fn load for each operating mode, and calculate Fnv for each mode and the resulting load for each half of the nut Fnv1 and Fnv2. These values help determine the equivalent mean load for each nut half, which helps estimate the lifespan of the roller screw assembly.

In addition to the nut type and preloading options, design engineers can select from cylindrical or flanged nuts depending on the overall assembly requirements and connection options. A common configuration is to capture a cylindrical nut in a tube and place a lock nut on the outside to ensure a secure connection and proper alignment. Design engineers can also specify a nut housing or carrier with threads or connections to the tube.

Regardless of nut type, wipers can be added to the front or back of the nut to clean the threads during operation. This protects the roller screw assembly from contaminants, assists with regular maintenance, and helps preserve the system’s life expectancy.

Check out the on-demand webinar relating to this topic at Design World.

Leave a Reply

You must be logged in to post a comment.