PM introduces the next generation of miniature slides: the MSR. This product has been developed according to the rising demand for smaller, compact linear slides for use in dynamic and accurate applications. The miniature slides are developed for increased output in micro-assembly machines and pick-and-place machines. The MSR miniature slide can also be used in applications for repetitive minor movements in tight spaces in combination with relatively high loads.

Six sizes

The miniature slide MSR consists of six particular sizes and is available in different lengths and strokes. The smallest is size 4, with a rail width of 4 mm and a stroke starting at 5 mm. The MSR range extends to size 15 with a rail width of maximum 15 mm and max. travel of 112 mm. The smallest miniature slide is the MSR 4 with an overall height of just a 4 mm and overall width of 7 mm and 10 mm length.

High loads and accelerations capabilities

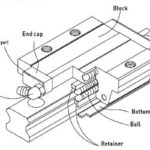

All parts are manufactured out of corrosion-resistant steel, for the bearings high-precision cylindrical rollers are used. These rollers are arranged in a crisscross pattern; meaning that each roller is oriented at a 90° angle relative to the one next to it and  being kept in a stainless-steel cage. This design enables the slide to support loads and moments from all directions and it also contributes to high stiffness. The max. acceleration is determined at 200 m/s2 and max. load capacity is 7.819 N.

being kept in a stainless-steel cage. This design enables the slide to support loads and moments from all directions and it also contributes to high stiffness. The max. acceleration is determined at 200 m/s2 and max. load capacity is 7.819 N.

Integrated Anti-Cage Creep mechanism ACCI

All sizes of the MSR slides are featured with an advanced and robust anti-cage creep mechanism. It will retain the roller cage in position under the most demanding conditions, like high accelerations and vertical mounting orientation. ACCI guarantees that the stroke always can always be achieved, even under the harshest environments.

Easy mounting – high precision

The miniature slide table and center rail have a standard attachment hole pattern with countersunk and treaded holes. This enables the user to mount the slide easily and simply into the application. All the miniature slides are in-house preloaded by means of geometry pairing of the cylindrical rollers within tolerances of just 0.5 µ. This results in nearly frictionless motion with a high precision stroke and a smooth-running behavior.

Unique Design

The MSR miniature slide is unique in its class. The combination of crossed roller technology and anti-cage creep mechanism in these small slide dimensions were previously thought of as impossible. The designers at PM have resolved a dilemma by placing these parts in a compact package.

Product link website: pm.nl/en/products/linear/linear-slides/micro-slide-msr

More information about PM, visit PM.nl

Leave a Reply

You must be logged in to post a comment.