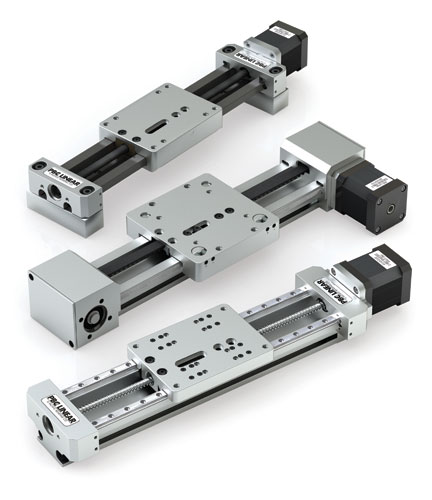

PBC Linear® introduces the SIMO® Series Linear Motion Platform, a family of linear motion solutions designed to be versatile, flexible, and affordable. Versatile options allow a design engineer to meet multiple application requirements with a single platform. Flexibility is due to consistent geometry creating a platform of interchangeable options.

The SIMO Series Linear Motion Platform range of options includes low profile rail for tight spaces or a tall version for greater structural integrity. Each aluminum base rail is uniquely qualified with the SIMO process (Simultaneous Integral Milling Operation) for six times less bow, two times less twist, and two times better flatness. The result is a base rail with machined precision at aluminum extrusion prices.

Three bearing tribologies are available: self-lubricating FrelonGOLD® plain bearings which are ideally suited for contaminated environments, V-wheel roller bearings for high speed applications, and profile rail linear guide ways with recirculating ball bearings for rigidity and precision. Three drive types are available: lead screw with machined nut or anti-backlash nut, ball screw, or two versions of belt drives.

This versatility to mix-n-match features within the same design envelope allows an engineer to test multiple configurations, easily adapt to changing requirements dependent on load, speed, accuracy, environment, or life considerations, and specify a linear motion system on budget and on time.

PBC Linear®

www.pbclinear.com

Leave a Reply

You must be logged in to post a comment.