Klüber Lubrication, a worldwide manufacturer of specialty lubricants, has introduced Klübersynth BR 46-32 F and Klübersynth BR 46-82, a series of specialty lubricants for the lifetime lubrication of actuators, which match the service life requirements of the automotive industry.

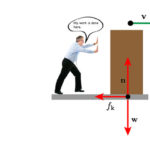

Actuators are power transmission elements that convert electrical signals into mechanical movement. However, for dependable actuator performance, their small mechanical components need to be lubricated reliably. Many applications in the automotive sector today use electromechanical elements in brake, steering unit or clutch mechanisms. The operating conditions vary according to the specific application and may involve very high or low temperatures and speeds, or rapid accelerations, along with minor actuating movements.

“Our partners in the North American automotive industry are using Klübersynth BR 46-32 F and Klübersynth BR 46-82 in the design of their innovative electromechanical braking systems, which help exceed their lifetime durability requirements,” explains Mike Norton, business development manager for chassis applications, Klüber Lubrication NA LP.

“The grease not only supports the operation of braking systems at both ends of the temperature spectrum, but also protects against false brinelling and wear, while maintaining compatibility with brake fluid and EPDM elastomers.”

Special lubricating grease for smooth operation in rolling contacts in electromechanical systems

In the automotive sector, components like rolling bearings, ball screws and small gears must have a low starting torque, even at low temperatures. The use of special seals is making the compatibility of lubricants a critical issue. Klübersynth BR 46-32 F meets the requirements, in terms of long-term lubrication, of components having rolling contact. This low-viscous special grease offers a good low-temperature behavior at -45°C, as well as a low friction torque, and therefore contributes to increasing energy efficiency.

Temperature-resistant speciality grease with solid lubricant additives

Clutch and brake actuators are equipped with planetary rolling contact gears or ball screws which generate minor actuating movements along with high acceleration. Klübersynth BR 46-32 F meets these requirements. The low viscosity base oil ensures smooth running at low temperatures and its oxidation stability allows safe operation at high temperatures. The unique lubricating grease is used for lifetime lubrication. It contains selected additives and solid lubricants which offer good wear protection under sliding conditions. Klübersynth BR 46-32 F also provides good compatibility with EPDM elastomers, as it contains the same base oil type as the other lubricating greases in the Klübersynth BR 46 series.

High wear protection for brake-by-wire components

Klübersynth BR 46-82 provides high reliability in a wide operating temperature range, e.g. in electromechanical brakes and parking brakes. The lubricating grease also offers good wear protection for ball screws and other power transmission elements at permanently high temperatures up to 180°C and at low temperatures to -40°C. The base oil is compatible with standard brake fluids and EPDM seals. Klübersynth BR 46-82 is a cost-effective alternative to greases based on perfluorinated oils.

Klüber Lubrication is one of the world’s leading manufacturers of specialty lubricants, offering high-end tribological solutions to virtually all industries and markets worldwide. Most products are developed and made to specific customer requirements. During its more than 80 years of existence, Klüber Lubrication has provided high-quality lubricants, thorough consultation and extensive services, which has earned it an excellent reputation in the market. The company holds all common industrial certifications and operates a test bay hardly rivalled in the lubricants industry.

Klüber Lubrication, set up as a retail company for mineral oil products in Munich in 1929, is today part of Freudenberg Chemical Specialities KG, a Business Unit of the Freudenberg Group, Weinheim. Klüber Lubrication has approximately 2,000 employees in more than 30 countries. For more information, visit klubersolutions.com

Leave a Reply

You must be logged in to post a comment.