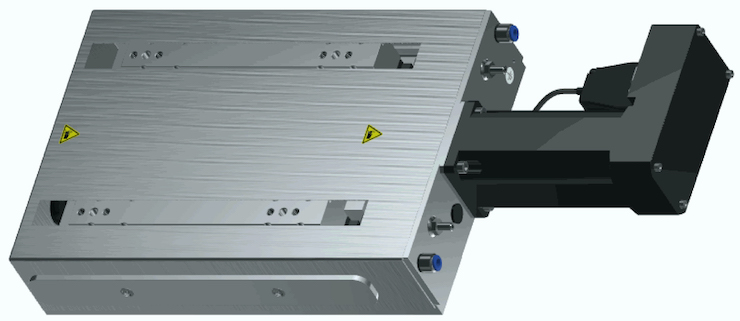

With the new TBS Linear Axis offering from ETEL, semiconductor equipment manufacturers can now integrate a high-precision linear axis enabling outstanding performance in term of accuracy and precision in its category of one-Degree-Of-Freedom (1-DOF) systems. With its ISO 2 rating for cleanrooms and incorporated HEIDENHAIN Group encoder technologies, the TBS provides high cleanliness and accuracy for any application needing to carry up to 45 kg of payload with high precision and stability of macro and micro motion.

The TBS 1-DOF mechanical bearing is based on an indirect drive linear axis that is controlled by a high-performance, low cogging servomotor using a dual encoder feedback control scheme. This is combined with specific design characteristics and options such as thermal decoupling of heat sources, high stiffness and a micrometric hard stop to ensure that its performance is maintained over a long operating lifetime, improving the end users’ ROI.

As part of ETEL’s commitment to providing high quality motion systems to the semiconductor market, the TBS is especially suitable for wafer process control applications such as overlay metrology, critical dimension and thin film metrology, as well as photonics.

The main features of the TBS Linear Axis include:

- Acceleration up to 0.5 g

- Payload up to 45 kg

- Position stability: down to ± 10 nm

- Bidirectional repeatability: ± 0.3 um

- Max. speed: up to 30 mm/sec

- Max. Acceleration: up to 5 m/sec2

- ISO 2 cleanliness (ISO 1 Optional)

ETEL S.A. is based in Switzerland with exclusive North American distribution through HEIDENHAIN CORPORATION in San Jose, CA and Schaumburg, IL.

For more information, visit www.heidenhain.us/product/direct-drive-motors-and-motion-systems/.

Leave a Reply

You must be logged in to post a comment.