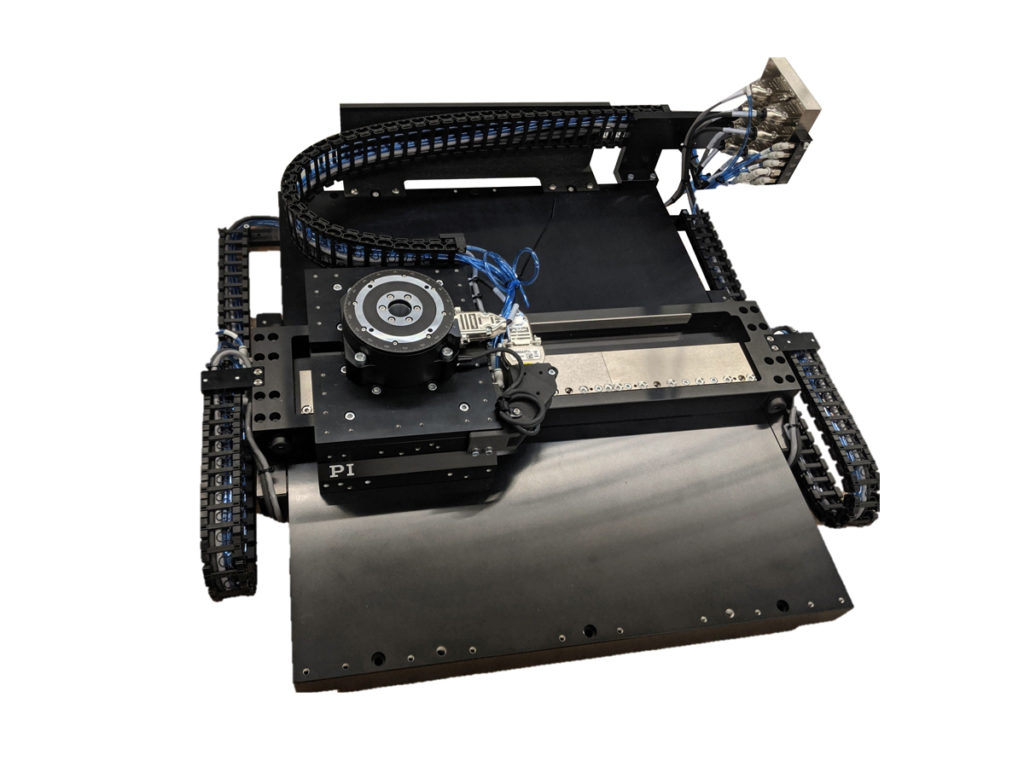

Our 2020 survey of the industry indicates an unabated trend towards more automation of previously static or manually tended systems. Key to these new offerings is installation simplicity for OEMs and end users of linear components for linear axes … as well as positioning stages and Cartesian robots.

In fact, Cartesian robots (also called linear robots) increasingly serve as turnkey solutions where tasks were previously done manually. That’s in part because (where suitable) linear-based solutions offer simplicity and precision at a price point that’s unrivaled by other solutions. So linear-motion adherents want these multi-axis arrangements to come to mind when laypeople and engineers alike discuss robotics.

“When discussing robotics, some people think of walking robots. Others picture consumer-grade designs or even toys and Japanese companion robots. Those in automation often conjure a 6-DOF robot or SCARA in their mind’s eye. I’d really like to change such preconceived notions — at least in our industry. After all, a gantry qualifies as a robot. It is taking human motion and it’s repeating it and it’s programmable,” says Macron Dynamics national sales manager Michael G. Giunta.

Giunta considers it a core mission to help industry recognize Cartesian arrangements as robotics.

“The official definition of robot is a machine capable of automatically replicating certain human motions and functions. So a linear-motion installation in a fast-food kitchen that picks up a fryer basket and moves it to a second location as a human would do is in fact a robot. In contrast, the Da Vinci surgical system is often called a robot, but technically it does not qualify — because its movements are ultimately controlled by a human being,” explains Giunta.

Trends in linear guides and guide rails, slides, and ways include more uses for profile rails and linear bearings with plain bearings and linear guide wheels. Our experts reported more configurability for both rails and shafts as well as carriages and runner blocks that traverse them. That’s to satisfy demand for flexible machines that employ modularity to adjust to changing processes for material-handling machinery, packaging, and other forms of factory automation. This year has also brought increased focus on hygienic component designs. Those in turn are supporting some newer automation industries — such as that for CBD or cannabis-related products.

“Machine builders are now using our products for automated watering systems as well as the positioning of lights and a whole range of tasks in the vertical and indoor farming industries,” says Matt Mowry, DryLin product manager at igus. DryLin products are also used in automated installations to support planting — especially for seeding and (after harvest) the pressing out of plant oils.

“Designers use our lead screws because they continuously run clean. If dirt does get on them, they still perform well,” adds Mowry. The self-lubricating screws need no oil, which is important to the CBD and cannabis market for meeting the standards for products meant for human consumption. “Plus the linear actuators are much lower in cost than actuators based on ballscrews … and maintenance free.”

Home hobbyists making routers and 3D printers are other users of these components. “Frequently, they get plans online and swap out the steel ball bearings with our bearings for higher consistency and self-lubricating nature,” adds Mowry.

Linear-actuation trend is to more precision

Ballscrew-based and newer belt-based linear actuators are associated with high precision on large motion axes … and miniature designs can in some cases employ leadscrew-based actuation to satisfy the same design objective.

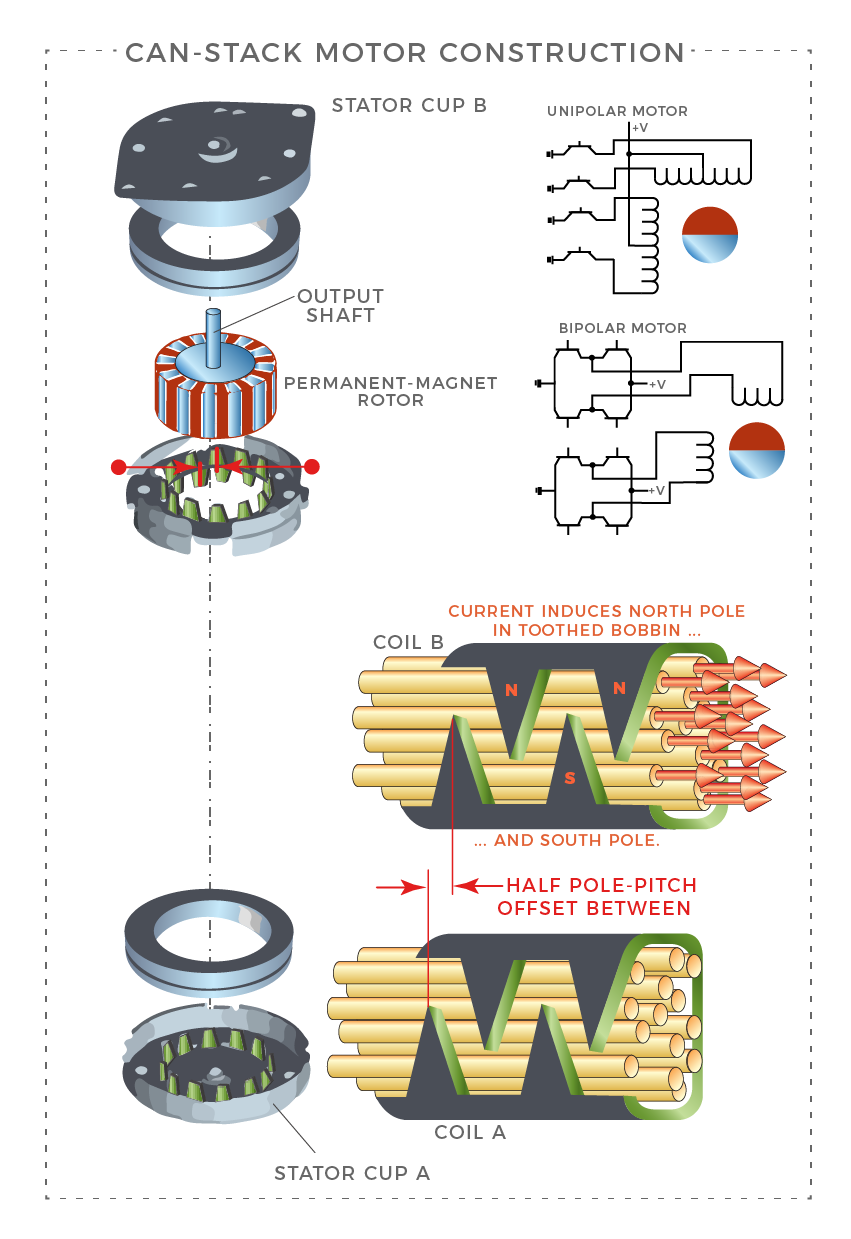

“Laboratory automation has always been a great fit for linear motion … especially stepper linear actuators. Of course, within certain laboratory devices, precision is required for moving samples into position, adding reagents, and withdrawing samples,” explains Dave Beckstoffer of Portescap. “Now, advancements in the linear force and speed capabilities of stepper linear actuators let device manufacturers increase their throughput with these actuators without sacrificing quality.”

The terms stepper linear actuator and stepper-motor linear actuator typically refer to can-stack stepper motors with a built-in leadscrew. “The laboratory devices are also rendered more adaptable to additional tasks and analysis thanks to the miniaturization of stepper-based linear actuators,” adds Beckstoffer.

Actuator suppliers also aim to ease installation

The past year has brought new electric actuators that complement battery-powered designs for mobile and off-highway vehicles, medical equipment, and transportation systems. These eliminate efforts related to successful integration for OEMs and end users.

Check out the Design World 2020 Trends article on shocks for another example of new motion applications in the off-highway industry.

“We recently developed a long-life electromechanical linear actuator to withstand harsh environments such as those associated with pantographs for the connection and disconnection of electric power in mass-transport applications,” says Anders Karlsson, product line specialist for linear actuators at Thomson Industries.

Karlsson also sees more buses, trams, and trains incorporating hybrid powertrains employing externally supplied electric power and batteries. “This means vehicles charge on overhead lines when available and then disconnect from the charging system to run systems off batteries … so there are high cycle counts for actuators in these vehicles. “Our Electrak LL delivers long life here — and meet rigorous railway standards.”

Another battery-powered application making use of linear actuators is automated guided vehicles (AGV) for material handling. Some AGVs necessitate 24/7 operation even if duty cycles never exceed 25% or so. “The stroke our compact HD actuator excels here — and with 10 times the life of a standard actuator, our LL is durable enough for inclusion on AGVs,” adds Karlsson.

Check out a new-use example here: Electric actuators help reconfigure rooms in futuristic flexible residential construction

Also read other articles from the Design World Trends issue at the 2020 Design World full Trends library.

Leave a Reply

You must be logged in to post a comment.