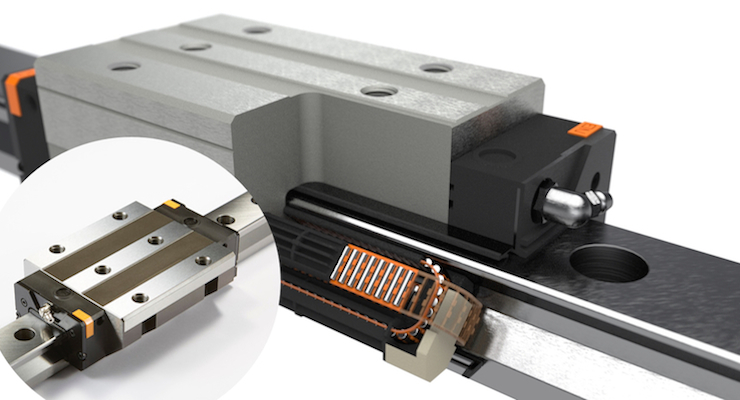

NB Corporation’s EXRAIL linear guide has more rollers in less space than other linear bearings, which increases load capacity and disperses the load more evenly. It has longer rollers for greater contact surface and less contact pressure.

In comparison to presently available linear guides, the EXRAIL slide guide provides smoother movement. It uses multiple small diameter needle rollers that reduce dynamic frictional resistance and range of fluctuation of dynamic frictional resistance.

Another EXRAIL feature is that its static load capacity is higher. Localized deformation occurs when a slide guide receives load in pitch, yaw, or roll directions. High static load capacity means that there’s a fairly large amount of load that the block can sustain before it deforms. In fact, for the new design, independent testing data indicated that it exhibited higher performance than presently available products.

The EXRAIL has a 1.5 to 2 times higher static load rating as well as allowable static moment in the rolling, pitching, and yawing directions in comparison to other products on the market. And the EXRAIL retainer prevents skews and friction ensuring smooth circulation.

Lubrication intervals are extended by EXRAIL’s maintenance features. Its rollers are in contact with lubricated resin material during circulation and its 4 oil holes make relubrication easy. It has side, under and inner seals that improve dust prevention.

For more information, visit www.nbcorporation.com.

Leave a Reply

You must be logged in to post a comment.