When we think of syringes, we typically think about the single-use type that doctors and nurses use to administer vaccines or individual doses of medication. But some conditions necessitate frequent or constant doses of critical medication, making it undesirable or even unfeasible to administer via single-use syringes. And in other cases, medications that would normally be administered orally can’t be taken by a patient for physiological reasons such as difficultly swallowing or adverse side effects that render oral medications ineffective.

When oral medication isn’t an option, medical personnel often choose to administer medication subcutaneously via a syringe pump.

According to the United States Food and Drug Administration, an infusion pump is “a medical device used to deliver fluids into a patient’s body in a controlled manner.” One way the FDA classifies infusion pumps is by their method of operation, which includes syringe pumps, elastomeric pumps, and peristaltic pumps.

Syringe pumps can be designed for stationary use in hospitals, clinics, and research labs, or for ambulatory (portable) use, to allow patients to move around and carry the pump with them, often in a shoulder bag or pouch.

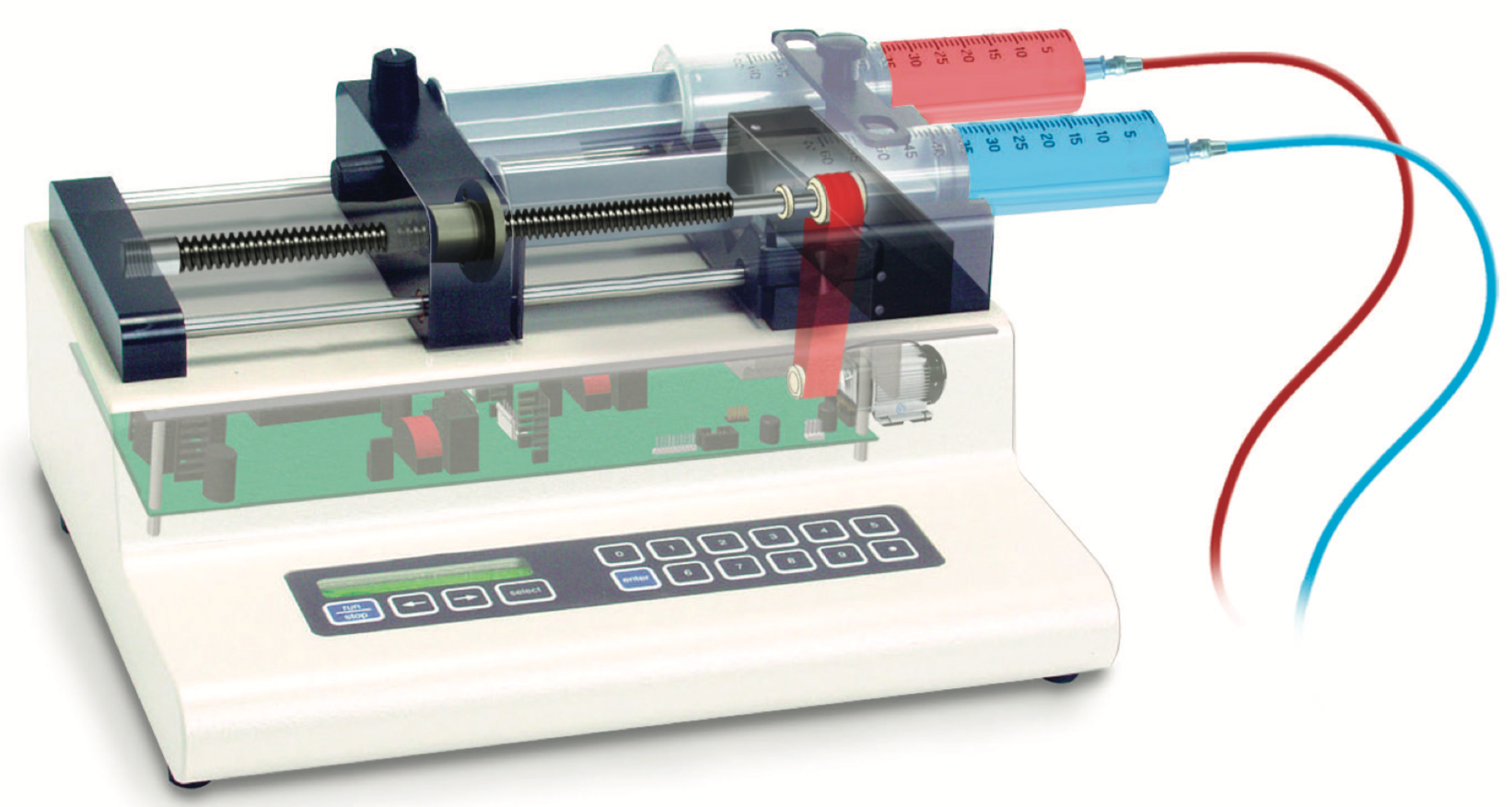

The basic premise of a syringe pump is that fluid (medication) is held in the syringe, and the plunger of the syringe is actuated by an electromechanical device to control the delivery of fluid to the patient. This electromechanical actuation is commonly achieved with a lead screw driven by a stepper motor. The lead screw nut is attached to a mechanism — typically a block — that pushes the syringe plunger by a specified amount at a controlled rate. The pusher block is supported and guided by two parallel shafts with plain bearings to ensure that it glides smoothly and without skewing.

The entire assembly is essentially a miniature linear actuator — made up of two linear guides, a lead screw, and a stepper motor.

Image credit: Chemyx

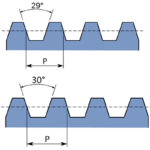

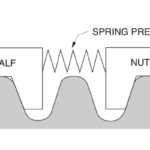

Like any medical device, lead screw syringe pumps are mission-critical, or as some refer to them, “life-critical” devices whose failure can compromise patient safety, so performance and reliability are paramount. Anti-backlash lead screw nuts ensure precise fluid delivery, and PTFE-coated screws with bronze or plastic nuts help reduce stiction, or stick-slip, in syringe pumps. And PTFE-coated screws eliminate the need for lubrication in syringe pump assemblies, where lubrication-free operation is typically mandated.

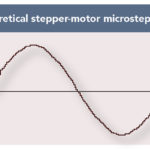

Precise control is key to delivering the exact volumes required for administering medication or performing critical laboratory research and testing, which often involves dispensing fluids in microliter amounts. Since the stability of the syringe’s flow rate directly correlates with the number of steps the motor can make, syringe pumps typically use stepper motors with microstepping control.

Size and weight are critical criteria in syringe pump designs — especially for those intended for ambulatory use — and the ability to customize lead screw nuts helps syringe pump manufacturers make their units as compact as possible. And because lead screws have no recirculating parts, they produce less noise than other drive mechanisms and help the syringe pump assembly meet low-noise requirements.

Image credit: BD

Leave a Reply

You must be logged in to post a comment.