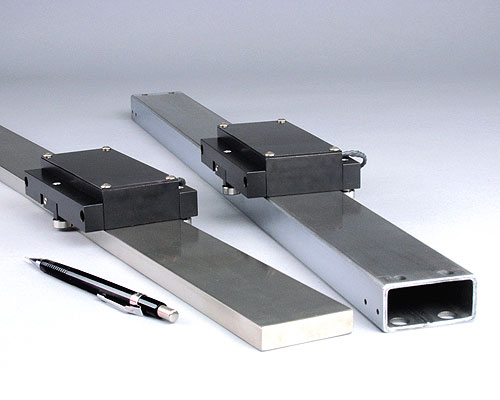

Santa Clarita, CA — Choose an easily integrated, low cost, high performance, 2-phase or 4-phase, linear stepper motor from H2W Technologies to improve the performance of an existing motion control system or create a new high speed, high accuracy system. These, compact, industry standard, 12 lb. Linear Steppers (53 N continuous Force, 16 lbs, 71 N peak force) travel at 80 in/sec. [2 m/sec.], with 1 micron [0.00004 in.] resolution, and can operate in any axis. Additionally, these 12 lb. Linear Steppers feature 1G acceleration and are the ideal choice for any of the following: New and existing gantry robots, pick-and-place systems, wire bonders, parts transfer, fiber optic, semiconductor, medical, and other precision robotic applications.

Available with a hard chrome, solid or hollow “platen” (track) in lengths up to 144 inches (3.65 meters), longer travels can be achieved by supplying the platens in sections, the H2W Technologies, industry standard, 12 lb. Linear Stepper is capable of very precise position, velocity and acceleration control when integrated with a microstepping drive and indexer. The resolution of these 2-phase or 4-phase motors is determined by the driver. One full step equals .010 in. [250 microns] and one microstep equals .00004 in. [1 micron]. Ideal for open loop positioning applications with moderate payloads, the “12 lb. Linear Stepper” can also be operated as a brushless linear servo with up to 5 Gs of acceleration and no loss of accuracy.

Capable of generating 12 lbs. [53 N] of continuous force, these single axis linear steppers have a forcer [motor], air bearings, side guide bearings, and platen [track] integrated into a compact, low-profile, package. The forcer connects to a motion control system via flying leads or “D” connector. Multiple forcers can operate on a single platen at the same time. Linear steppers can also be custom designed to meet a particular application’s requirements. Complete motion control packages including and indexer and driver for open loop operation or encoder, motion controller, and driver for closed loop brushless servo motor operation are available from H2W Technologies.

H2W Technologies, Inc.

www.h2wtech.com

Leave a Reply

You must be logged in to post a comment.