Lack of bearing lubrication is generally regarded as the number one cause of linear-bearing failure.

For recirculating linear bearings such as profiled rail guides and ball screws, lubrication separates the bearings (ball or roller) from the raceways, minimizes friction and wear, dissipates heat, and prevents corrosion. It also promotes smooth running of the seals and reduces seal wear, ensuring their effectiveness in keeping the bearing lubricant in and keeping contamination out.

Image credit: The Barden Corporation

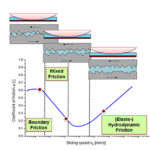

The theory of elastohydrodynamic lubrication defines the conditions for development of a lubricating film in recirculating linear bearings. Simply stated, the formation of the lubricating film is dependent on the viscosity of the lubricant, the speed of the bearing, and the pressure between the bearing and the raceway.

For profiled-rail guides and ball screws, lubrication can be achieved with either grease or oil. The choice depends on the application parameters, including: temperature, load, vibration, speed, environment, contamination, and stroke length.

Benefits of grease for linear bearings

For most linear guide and drive applications, grease is the better lubrication option. It adheres to bearing surfaces better than oil, lasts longer, and is less likely to run off or be ejected from rotating parts.

Grease lubricants are made of three primary components, a base oil, a thickener, and additives (typically rust inhibitors). When selecting a grease lubricant, the viscosity of the base oil determines how the lubricating film, which separates the rolling elements from the raceways, develops. The consistency class of the grease, which is defined by the National Lubricating Grease Institute (NLGI), indicates how the grease will flow and disperse within the bearing.

Linear systems typically use lithium-based greases, with no solid additives such as MoS2 (molybdenum disulfide) or PTFE (Teflon), in consistency class between 0 and 3. These greases perform well in high-load applications and have good stability against oxidation.

When to use oil for linear bearings

Oil lubrication is recommended for high-speed applications, because it dissipates heat more readily than grease. It also flows and disperses better than grease. But when oil lubrication is used, the orientation of the bearing and the location of the lubrication ports must be taken into account. When components are mounted on their sides or vertically, oil lubrication will not flow to bearings and raceways that are above the lube ports.

Image credit: NSK Precision America

Some machine builders employ a misting system for oil lubrication. Although these systems can be more complex and costlier than manual or even automated systems for grease lubrication, an oil mist system provides the additional benefit of creating positive pressure inside the bearing. This helps prevent contamination from entering the bearing and further assists in cooling.

It’s important to note that incompatibility between lubricants can cause separation of the lubrication components and render it ineffective. Some manufacturers provide linear guides and ball screws that are pre-lubricated, ready to install and use, while others simply apply a preservative grease or oil. To ensure compatibility between the initial lubrication and the in-service lubricant, check the manufacturers’ lubrication specifications. If the two are not compatible, components should be wiped down and purged before any additional lubrication is applied.

Regardless of the lubrication type — grease or oil — maintaining the proper amount of lubrication is critical to achieving optimum bearing life. Manufacturers of linear guides and ball screws publish recommended lubrication quantities and intervals, which are primarily based on the type of lubrication being used, along with the speed and temperature of the application. Other factors, such as shock loads, vibration, and contamination can also affect the life and performance of the lubricant. For applications with these conditions, lubricant manufacturers can analyze the operating parameters and recommend a lubricant that will ensure optimum bearing life.

Very good tech article

Worthwhile article, air-oil lubrication is one of our specialties, the paragraph on air-oil or mist for linear bearing agrees with our findings. The angle and position as well.

Don Schaefer Bijur Delimon Intl

sir,

i m very happy to see the explanation about the lubrication. what are the recommended lubricant for gear motor. what are the bearing type need to replace in gear.